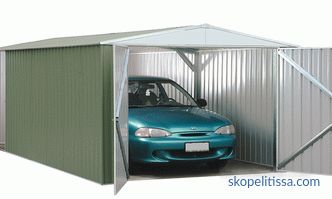

All car owners are very responsible for building a garage. After all, this is, in fact, the house of the car, where it will not only be preserved from the effects of natural loads, but also be safe in terms of safe storage. Therefore, garages are built from reliable building materials, and reliable gates are hung on the gates. In this article we will talk about the garage of corrugated flooring, namely, which brand of profiled sheets should be used for cladding the structural elements of the garage, how the installation of sheet material is carried out and what points you need to pay attention to when constructing a garage structure.

What is profiled

Much has been written about this material, and every person has already met him. But since we are talking about facing the garage, it is necessary to understand that not every brand of this material is suitable for this. Although it all depends on where the garage will be built.

For example, if this building is being constructed inside a suburban area, that is, it will mainly perform purely protective functions from precipitation, sunlight and wind, then wall sheeting made of thin steel sheets can be used (up to 0 4 mm). This type of profiled sheet has a low bearing capacity and burglary resistance.

But since the garage structure itself is located on the territory of the suburban area, that is, almost under constant protection and supervision of its owners, it is possible to treat burglar resistance with some relaxation.

If a garage is a stand-alone building located outside a protected area, then it is better treated as a building that can be hacked. That is, not every professional flooring brand will be suitable for finishing. For this, it is better to use sheets with a thickness of at least 0.5 mm and a wave height of at least 21 mm.

But as for the roof, it is better to use profiled sheeting made from a minimum thickness of sheet 0.5 mm and a wave height of at least 40 mm. Because it is a roofing material with a high bearing capacity. And it is he who will be able to withstand all the loads acting on the roof of the garage, mainly snow cover in winter.

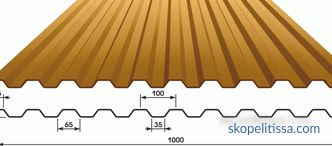

Pay attention to the thickness parameter. It can be confused. There is a total thickness, that is, it is the thickness of a galvanized steel sheet, plus layers of paint or polymer composition. It does not take into account. Although it is precisely this size that is often measured on the market to make sure that it corresponds to the size declared by the seller. Usually this indicator is more than required. Therefore, very often sellers give the total thickness for the standard, making a lot of money on it.

It is necessary to take the thickness of a galvanized steel sheet as the basis for selection. It can not be measured in a professional flooring, so manufacturers must indicate this parameter in the marking. For example, С21-0,55-750-2000. Digital designation 0,55 - this is the thickness.

Advantages and disadvantages of profiled flooring in garage construction

Profiled sheets are considered to be the ideal material used in the construction of small architectural forms. Because:

-

Its installation - the process is fast . A small garage can be assembled from a profiled sheet in one or two days .

-

Easy to install and fasten the sheet material, for which roofing screws are mainly used.

-

Low cost garage construction. First, the decking itself costs relatively inexpensive . Secondly, the services of craftsmen who will veneer the garage with profiled panels are also inexpensive , because this is a very simple job.

-

A garage construction , lined with professional sheets, will last a very long time . There are examples of thirty-year operation of such buildings.

-

By itself a garage of this type - is a light structure . It can easily be moved or moved .

Our site contains 27 of the most successful projects of garages from 106700 rubles. And also you can familiarize yourself with the most popular projects of other buildings - bathhouses, gazebos - from construction companies represented at the exhibition "Low-Rise Country".

-

Decking - material metal , so small architectural forms erected from it are objects that fully comply with standards and fire safety requirements .

-

Coated or polymeric compounds with profiled sheets cannot

of metals . In addition, the raw material - there is a galvanized steel sheet.Hence, in principle, the long-term operation of garages. -

The profiled flooring can veneer garages of frame type . In this case, the frame can be made of metal shaped pipes , angles , lumber or LSTC .

As for the drawbacks, there are only two of them:

-

High thermal conductivity of metal panels. If you want to build a warmed garage, you will have to carry out heat-insulating measures . This also applies to walls of construction , and roofs .

-

Regardless of sheet thickness and profile height, all professional flooring brands lose their shape with strong shock loads . Return the original appearance after this is impossible. But the profiled panels easily can be replaced . So the problem is solved easily.

The most popular manufacturers and construction companies are assembled at the exhibition and presented at our site. Here you can find contacts, choose and order any service, including installation of metal structures (sheds, greenhouses, etc.), roof repair, construction of fences and fences. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

The rules and sequence of the construction of a garage of corrugated

Garage construction is a responsible structure. Because during its construction it is necessary to take into account a large list of different conditions. For example, when choosing a place to install a garage, you will need to think about convenient access. Or will it be convenient to open the garage door, will they not interfere with something.

It is very important to consider the height of the structure. This primarily concerns the entry, so that it fully corresponds to the height of the car. In this case, the garage should not be lower than the neighboring buildings. Because the snow and rain from the neighboring roofs will flood your garage.

Now we need to resolve the issue with the frame. Usually, profile pipes with a cross section of 20x40 mm with a wall thickness of 2 mm are acquired under it today. This is an inexpensive material by comparison, but in a garage construction it acquires a rather high bearing capacity, sufficient for a small architectural form.

Of course, there are offers of garages with a frame from a steel corner of 40x40 mm or from sawn timber. The latter are usually collected in areas where wooden houses were built, and there is a lot of waste or good material left. But such models are rare.

Foundation for a garage

As mentioned above, a garage assembled from profile tube and sheathed sheeting, the structure is light. Therefore, under it does not make sense to fill a powerful foundation. Usually, a slab structure is poured in, which will simultaneously serve as a garage floor. If there is a need, then immediately make a viewing pit. Although the latter is not always necessary today. Not everyone can repair modern cars. The maximum that a car owner can do is to change the wheel or spark plugs. And for this inspection pit is not needed.

The dimensions of the foundation should be 20-50 cm more than the size of the garage. At the same time, the driveway must also be equipped immediately. It is poured under a slope so that rainwater or melt water does not get inside the building.

It could be interesting! In article on the following link, read about how to properly done shed roof of corrugated on the garage.

Garage frame

The basis of the building is built according to the parameters of the building. At the same time, it is important to understand autumn that profiled sheeting is laid on at least three support posts: one should go in the middle of the panel, two at the edges. Sheet material and must be attached to them. For example, if the length of the garage is 6 m, then the racks of the profile pipe are installed every half meter, because the useful area of almost all brands of professional sheets is 1 m.

For everything else, the frame of the garage is no different from other structures, sheathed by other building materials. In fact, these are three walls: one short back and two long side, plus the roof. The latter can be single or dual. The main thing is to create an optimal water flow so that it does not get inside the building.

The video shows how a slab foundation is poured under the garage and a frame is made of a profile pipe on it:

This could be 48> interesting! In the article on the following link, read about why many people just want to build a new house.

Installation of professional flooring

Regardless of whether a flooring is used for garage walls or for roof covering, the technology of its installation and fasteners is the same.Namely:

-

Profiled sheets stack overlap relative to each other in one wave .

-

Roofing self-tapping screws are screwed into the plane of the lower wave .

-

The fasteners are screwed strictly perpendicular to the pressing plane. No distortions, especially on the roof of the building. Because skewing is a loose clamping of the rubber gasket of the screw that seals the mounting hole.

-

It is impossible to strongly tighten the self-tapping screws , you cannot also do not screw in the . It is necessary to ensure that the cap of the screws and the gasket are pressed tightly to the frame of the garage.

-

To start installation of profiled sheets should be from the corner of the garage construction . In this case, first screw the screw into the upper angle of the panel from the side of the corner of the building. After that, the sheet is aligned vertically, and then the second screw is screwed into the opposite corner of the sheet. And after that they carry out fixings along the edges of the corrugated flooring, as well as in the middle every 30 = 40 cm on the walls, and 15-20 cm on the roof.

After the installation process associated with the installation and fastening of profiled sheeting it is required to additionally ensure the tightness of the whole structure. This mainly concerns the ridge, if a gable roof is being constructed, and the corners of the building. To do this, use special additional elements made of the same material as the profiled sheets themselves. The ridge is covered with a two-meter element called a ridge. The corners of the building are covered with corners, the length of which is basically 1 m. They fix the fittings to the roof and walls of the garage with small metal screws. The fastener is carried out in the upper wave profile.

The video shows how to properly install corrugated roofing on the garage roof:

This could be interesting! In the article on the following link read about the new project of the house from the architect studio Lucciano Crook: a combined cottage - concrete and wood in Argentina.

Conclusion on the topic

If someone is cramped in finance, and a garage in a country plot or in another place is very necessary, then the simplest option is a garage construction assembled from a profile pipe and sheathed profiled sheets. The main task of the manufacturer is to choose the right profiled panels themselves in terms of sheet thickness and profile height. This applies to walls and roofing.