Liquid concrete is an aqueous solution of a viscous consistency of components taken in certain proportions. After curing, it becomes a strong, reliable, resistant to mechanical stress and natural phenomena material.

Experienced builders advise you to make concrete mix yourself, rather than buy ready-made. To prepare or determine material costs, you need to know exactly how much cement is needed per 1 cubic meter of concrete for the foundation. The calculation of the components is carried out according to a special system, and a number of factors must be taken into account.

The brand of concrete for the foundation

First of all, it is necessary to determine which concrete brand is suitable for building a foundation for a particular house on a given soil. The foundation must have sufficient strength, rigidity and mobility after curing the mixture.

It is advisable to fill the foundation of the house with concrete that has all the necessary properties for this :

- M100 or M200 is absolutely not suitable for this purpose. However, some gardeners strengthen lightweight structures using the M200. Experts do not recommend risk, such a building structure will not be reliable.

- The M300, M350 grades are suitable for the construction of the foundation. M300 is most suitable for technical specifications for private construction. M300 allows you to get a solution of good quality, is offered at affordable prices.

- M400 is used for foundations in the construction of industrial buildings, special-purpose objects.

A house built on a solid foundation will stand for many years without destroying the structures and cracks in the walls.

How to know the amount of cement

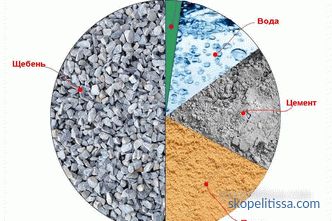

Concrete is a building material that includes sand, gravel or crushed stone, cement and water.

There is a special regulatory document on the basis of which professional estimators calculate the materials necessary for the preparation mixes. However, in the private construction of low-rise buildings use simplified formulas.

The quantitative content of cement in the solution determines the properties and brand of concrete. Even a small deviation from the optimal value affects the quality of the solution.

Arithmetic method

Individuals use a simplified system to find out how much cement is needed per concrete cube for the foundation, the calculator greatly simplifies the process. For this purpose, the following actions are performed:

- cement, sand and crushed stone are taken for concrete in the ratio 1: 3: 5, 1 + 3 + 5 = 9 - 1 m consists of 9 equal parts 3 mixtures;

- 1 m 3 = 1000000 cm 3 ;

- 1000000 cm 3 / 9 parts = 111111cm 3 - the volume of cement required to obtain 1 m 3 concrete;

- the specific gravity of cement 3 g / cm 3 ;

- we translate the volume into mass: we multiply the volume with a specific weight, we get 333333g = 333.333kg.

On our site you can find contacts of construction companies that offer the service of designing houses. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

In this way we will know how much cement is needed per 1 m3 of concrete, taking into account the error, 333 kg of cement are required. A bag of cement, in standard packaging, has a weight of 50 kg. Consequently, the number of bags of cement per 1 cubic meter of concrete is needed 6.66 or approximately 6.5 pieces.

How accurate is arithmetic

This scheme allows one to determine almost exactly the content of the material of the M100 brand. For other brands, this counting system is conditionally correct, and the resulting number is only an approximate value. It is advised to determine the mass of cement with an accuracy of 1 kg, crushed stone - up to 5 kg.

When you hover the mixture, you need to know that the 10-liter bucket holds:

- 15-17 kg of cement or rubble;

- 14-15 kg of sand.

It is known that the higher the grade of concrete (density and strength) to be obtained, the fewer bags of cement will be required.

Approximate table data

Approximate consumption of cement per cube of concrete for the foundation, depending on the brand used, is presented in the tables:

- mixture prepared on the basis of M300

| Concrete brand | M250 | M300 |

| Required mass of cement, kg | 340 | 300 |

- based on M400

| Concrete brand | M300 | M400 |

| Required cement weight, kg | 350 | 300 |

As the amount of cement of a particular brand changes, the concrete grade changes. The values indicated in the table depend on the quality of the soil and the size of the crushed stone material; therefore, they may change up or down in the calculations.

Does it make sense to use the M500 for the foundation?

Using the arithmetic method or tables, it is not difficult to know, for example, how much cement M 500 is needed per 1 cubic meter of concrete for the foundation. Not less than 8 bags or 400 kg for receiving the M400 solution used for construction of the bases in professional construction.

It is not desirable that 1 cubic meter of concrete contains more than 350 kg of cement. An oversaturated foundation after the final evaporation of moisture will be subject to severe cracking. Therefore, it is not advisable to use the mark M500 for targeting concrete under the foundation. This material is intended for other purposes.

Features of the right choice

Cement is ground mineral powder. In the concrete mixture, it is the only binder that holds sand, crushed stone or gravel together.

The brand of material is chosen taking into account the technology of concreting. Error leads to excessive consumption of concrete, distortion of proportions for other components. The base having the wrong composition will not last long, and after a while it will be necessary to carry out repeated works.

The following parameters are important when choosing cement:

- compressive strength (this parameter determines the strength);

- the presence of impurities;

- grinding quality.

Cure speed, hydrophobic properties, resistance to low temperatures, and operational requirements also affect the choice of material.

Previously, the marking M100-M500 was used, the number showed strength in kg / cm 2 . Since 2003, the rules have changed. For private construction, cement with the strength class B32.5 (M300) is popular. It is offered at affordable prices, it has the necessary technical characteristics for the foundation, withstands a pressure of 300 kg / cm 3 .

More details on old and new markings are featured in this video:

That might be interesting! In the article next link read about fiber cement panels.

Types of cement

Depending on the proportions of the incoming components, this material is divided into several types:

- portland;

- slag portland;

- pozzolanic;

- fast-hardening.

Portland and the fast-hardening variant are most often used for foundations. Portland cement contains the minimum amount of impurities, which allows to improve the quality of the mixture by including additional elements. Fast cement is offered at an inexpensive price, has good performance characteristics.

How much water is needed

When counting the amount of materials per 1 cubic meter of concrete, it is dangerous to make a mistake when counting water for mortar under the foundation. Disturbance of proportions leads to a too thick or liquid solution that is not suitable for strengthening the building.

According to the methods for calculating the water-cement ratio, the ratio is 1: 2. For one portion of the dry mixture take half a serving of water. The amount of water affects the consistency and brand of solution. The more water, the less viscous the concrete.

For example, on the basis of cement M400, you can make concrete of any brand, pouring water in different quantities:

| Concrete brand | Water ratio / cement, l / kg |

| M200 | 0.69 |

| M250 | 0.57 |

| M300 | 0.53 |

By multiplying the weight of the cement (in kg) by the corresponding number in the table, you will find out the amount of water in liters. The table is valid if medium crushed stone is used.

Peculiarities of solution guidance

When building small private houses, the concrete mixture is often prepared on its own. The procedure involves the gradual introduction of water into the dry composition, followed by thorough and constant mixing of the solution to prevent solidification.For this purpose it is recommended to use a concrete mixer. Pouring work should be carried out in a short time, until the induced solution has lost the desired viscosity.

Component quality requirements:

- Cement fractions are distinguished from 5 to 20 mm by sieving through a sieve. Suitable dry, loose cement.

- Sand should not contain unnecessary impurities. After sifting, sand with fractions from 1.5 to 5 mm is isolated.

- Gravel or crushed stone is of medium size, in the range of 8-35 mm.

- Water should not contain an increased amount of unnecessary chemical elements, to be heavily polluted.

In a wet environment, the cement quickly dampens, lumps form. Given this, they acquire it immediately before use. In the absence of experience, you should choose crushed stone of medium or large size. Large stones provide a more dense structure of concrete and do not allow the appearance of air bubbles.

High-quality casting of the foundation requires removal of air bubbles or cavities from the concrete mass, which always appear during the casting process. To this end, the concrete mass is compacted with the help of specialized vibration installations for construction.

The unequivocal answer is - is it?

The answer is, how much cement is needed per 1 cubic meter of concrete for the foundation, or how much concrete from the bag of cement will turn out exactly, definitely not. It all depends on what kind of concrete should be used to fill the foundation for a particular house. The choice is influenced by:

- the size of the future house and the building materials used, determining its weight;

- soil characteristics: the groundwater level, the depth of frost penetration.

The table below shows the contents of the components necessary for targeting concrete of the most popular brand - M300 - depending on the degree of mobility of the mixture:

| Brand concrete | Mix mobility | Material consumption | |||

| Cement M300, kg | Crushed stone, kg | Sand, kg | Water, l | ||

| M300 | 1-2 3-5 6-8 9-12 | 335 360 380 400 | 1220 1202 1215 1200 | 636 630 588 560 | 155 165 175 185 |

For reasons of economy it is advised acquire cement of a higher grade than you need to get concrete. Concrete brand is always lower than cement.

It can be interesting! In the article next link read about fiber cement panels for facades.

Conclusion

At first glance, it is not difficult to prepare concrete for the foundation. However, this is the most critical part of the work during the construction of a residential building, errors in pouring the foundation will affect further work and operation. The cement calculator for the foundation, although it helps to calculate the amount of concrete, but these will be inaccurate numbers, and you can hardly guess the proportions, especially if you have not seen building materials in your eyes before. In many cases it is advisable to turn to professional craftsmen.