Today, the article will deal with a brick pipe on the roof. What kinds they are, from which brick it is better to lay down the pipe on the roof, the positive and negative characteristics of the brick structure, and also describe how the masters put the chimney out of bricks, that is, the sequence of operations carried out step by step. Be sure to confirm the story with photos and videos.

Types of brick pipes

There are three types of brick chimney designs that differ in location.

-

Aboriginal , they are also attached stovepipes. They are constructed separately from the furnace, that is, they are erected near the heating element, connecting the latter with a chimney tap (pipe). Usually such chimney pipes are installed where it is necessary to connect several stoves or fireplaces.

-

The mounted version . This is the most common type of chimney. By the name it becomes clear that the structure is installed on top of the stove, as if it is stuck on it.

-

Wall structure . It is constructed on the outer wall, that is, the structure is located outside the house, and not inside, as the two previous options. In this case, the wall pipe can be either mounted or root. This is the easiest option in terms of the construction of the chimney, but more expensive, since it requires a large amount of thermal insulation work.

Construction of the chimney

In the article we will talk about mounted model, as the most frequently used in the Russian region. The chimney consists of (up from the furnace up):

-

The neck of the furnace . In fact, this is a pipe of rectangular bricks. The area of the neck is selected for the capacity of the furnace. The greater the power, the greater the cross section. A steel valve is installed in the neck with which the chimney cross-section is adjusted. With its help air supply is regulated.

-

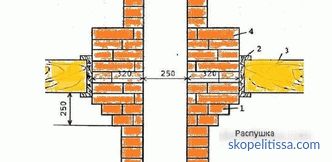

Bowing . This is an expanded brickwork, which is erected in the place of overlap between the rooms and the attic. Its purpose is to protect the ceiling from high temperatures. Essentially, a fuzzy is still the same pipe, only it has more wall thickness.

-

Riser . This is the longest part of the chimney that runs through the attic. Its cross section is the same as the neck of the furnace

-

Otter . The same design as raspuska. The purpose is to protect the roof structure from high temperatures emanating from the pipe, plus strengthening the chimney in order to withstand wind loads.

-

The neck of the chimney on the roof of a brick. This is the part visible from the outside, towering above the roof of the house.

-

Ogolovok . Its purpose is to protect the neck of the pipe from smudges, which usually occur on vertical surfaces during precipitation. That is, the outer diameter of the tip is larger than the diameter of the pipe gang.

-

Cap . This element of the chimney structure is usually made of galvanized steel sheet. Purpose - to protect the chimney shaft from falling into atmospheric precipitation.

On our site you can find contacts of construction companies that offer services for the design and repair of the roof . Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

General requirements for chimney

Regardless of the type of chimney, there are three strict rules that must be followed when building a pipe:

-

Exact selection of height brick construction.

-

From which brick lay the chimney over the roof.

-

How to use masonry mortar for this purpose.

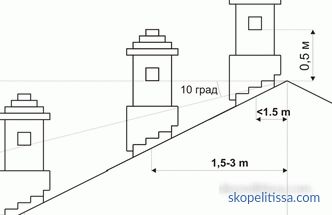

As for the height, this parameter is calculated taking into account the angle of inclination of the roof structure. To make you understand what is at stake, look at the photo below, which shows the ratio of the size of the roof with the height of the chimney.

It is important to understand that a properly selected height of the pipe structure is first of all good traction inside the pipe, which ensures proper operation of the stove. Secondly, this is compliance with the standards and requirements of fire safety. This mainly applies to roofs assembled from combustible materials. Because the turbulence of air masses can cause caviar to hit the roof. And it often becomes a cause of fire.

Now go to the bricks. Everything is simple here.

-

Parts of the pipe that are exposed to high thermal loads should be assembled from a fireclay (refractory) brick. This mainly refers to the neck of the furnace.

-

The remaining parts can be lifted from the red brick of the M200 brand. This material easily transfers temperatures to + 800C.

It can be interesting! In the article on the following link read about the roof overlapping of the house: the composition of the roofing pie and the choice of materials .

Important - buy bricks with smooth surfaces only. They will not allow soot to settle on them, which, after many years of operation of the furnace structure, narrows the diameter of the chimney, and this is a decrease in thrust. Plus - soot often causes ignition inside the pipe.

Now for the masonry mortar. Masters use two of its varieties: clay and cement-clay. Both materials easily tolerate high temperatures without cracking. It should be noted that in building stores dry mixes for brick laying in chimneys are sold. So in this regard, there is no problem.

And other requirements for the chimney according to SNiP41-01-2003:

-

One chimney for one stove.

-

Crossing of a pipe with other engineering communications is unacceptable.

-

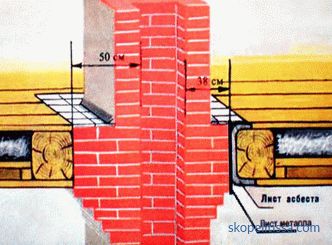

The distance from the brick pipe to the floor elements assembled from combustible materials is not less than 38 cm.

-

The passage of the chimney construction through the building elements and components should be formed from non-combustible materials located from the pipe itself at a distance of 25 cm.

-

Deviation of the axis of the pipe structure from verticals possible, but not more than 30 °.

-

Deviations must be rigidly attached to the building structures of the house.

-

It is necessary to provide hatches and windows that will have to be used to clean the chimney.

-

The part protruding over the roof should be only vertical .

It could be interesting! In the article on the following link, read about the stages of roof design: drawing up a project, calculating the roof .

The technology of building a chimney made of brick

So, laying brick brick on the roof should be foreseen at the stage of building a house. So it will be easier to carry out the whole process of construction. That is, it will not be necessary to make holes in the ceiling and roof structure. It is necessary to add that the mounted version rises with the stove. There is no other option here. Pristyazhnoy (root) or wall can be erected after the installation of the furnace, as both designs are separate.

In fact, the construction of a brick chimney is simple. But the process of its erection itself is complicated, because each row of bricks to be laid requires the master to precisely place them with horizontal alignment of each row. At the same time, it is very important to achieve evenness of the vertical planes that form the inner tube. That it is the most important element of the whole structure, because it depends on the draft and the efficiency of the heating equipment.

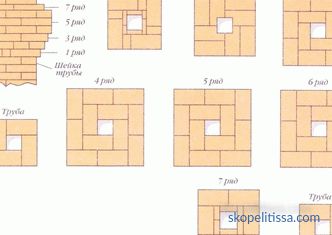

There are several brick layings in the chimney structure. But the easiest is shown in the photo below. Note that the laying is carried out in half a brick, and this is enough to speak about the effectiveness of the assembled structure. It’s not the bricklaying method itself or the installation of bricks that is important here, it’s important to observe the cross-sectional area of the inner strip.

That is, it turns out that the chimney construction trunk is erected above the stove almost equally over the entire height of the structure. The only deviation is a fuzzy and otter, where the bricks are laid in a more extended position. We offer to watch the video.

The video shows how the neck of the pipe, the otter and the tip are built above the roof:

Of course, we must pay tribute to the foremen who know in what order each row should be collected. And if the strut and necks are collected in the same way, then the ouster and otter are complex parts. Here, each row of bricks is its own special design. The photo below shows step by step how to assemble each row of rags.

Advantages and disadvantages of brick chimneys

Let's start with the advantages brick smoke pipes:

-

The main one is a long service life . Many examples can be cited in which brick chimneys have served for over 1000 years.

-

The thermal conductivity and heat capacity of the brick allows the chimney to act as an additional heating element. This is true in houses of several floors, especially for the attic.

-

Aesthetic qualities bricks should also be placed in the category of "advantages" of this type of construction. This building material will perfectly fit into any interior design of the house.

It might be interesting! In the article on the following link, read about the main fears about houses from CIP panels - the mythology of construction .

In principle, the benefits end there. The rest is only disadvantages:

-

Difficulty laying of the chimney above the roof and throughout the rest of the height.

-

Construction of a brick structure takes a lot of time .

-

This is heavy construction , under which you need to pour a solid and reliable foundation. And this is an additional cost.

-

If a stove with a chimney is being built in an already operated building, then it will be necessary to rebuild many rooms with holes in the ceilings and the roof.

-

Brick chimneys cannot be operated above the stoves , whose carbon monoxide gases have a low temperature. For example, over pyrolysis boilers. Because the inside of the pipe will form acid condensate, which simply “corrodes” the brick, causing it to become unusable. And this is not so far from the destruction of the chimney.

-

A large structure in section occupies a sufficiently large space in the room.

-

The rectangular shape of the internal section of the mine is not the best option. In round section smoke and gases flow better, which means that the draft of such chimneys is better. In private homes to collect round tubes will not work.

It should be noted that the most difficult moment - this is a passage of a construction made of bricks through the overlap of the building and roofing. Here it is necessary to take into account the requirements of SNiP and fire safety regulations. The main thing is to conduct insulation correctly, especially with regard to building components constructed of combustible materials. And this is usually the roof truss system.

The video shows the technology of the passage of a brick chimney through the roofing structure of a house:

It might be interesting! In the article on the following link read about design highlights - a collection of furniture from colored sand .

Conclusion on the topic

It should be noted that brick chimneys gradually lose their positions. They were not replaced by chimneys assembled by the type of a bell-shaped structure, made by the type of a sandwich, that is, two metal pipes, between which thermal insulation material was laid. In this case, the pipes are made of stainless steel, which guarantees long-term operation of the chimney. But statistics show that traditions are honored by our people, so brick pipes are still being built.

Rate this article, we tried for you