A garage for a car owner is a necessary structure. It is built from different materials: metal, brick, blocks, wood. In this article we will deal with the blocks for the construction of the garage. What they are, what components they are made of, and also denote their technical characteristics.

Types of blocks

Actually, the types of piece block materials on the market not so little. They differ from each other in the number and variety of components, and more precisely, the difference in one is the composition.

According to this principle, wall blocks are divided into the following types:

-

concrete ;

-

cinder blocks ;

-

of cellular concrete : foam and gas blocks;

-

gas silicate .

Consider each species separately, we denote their characteristics.

Concrete blocks

It is necessary to begin with the fact that this kind of wall material is a pure concrete product. There is nothing more than cement, sand, crushed stone (gravel) and water in it. Hence the high strength of the product.

Concrete becomes durable as a stone when dry, so structures made of concrete are often called artificial stone. But it should be noted that the concrete used in the production of blocks may be different. Hence the different characteristics of this material.

For example, blocks of heavy concrete, the density of which varies in the range of 1800-2500 kg / m³. It turns out that this is only because the composition of the recipe uses a large stone of heavy and durable rocks: basalt, granite, diabase, limestone and so on. Note that heavy concrete blocks are expensive, and more often they are used for the construction of foundations.

Light concrete blocks with a density of up to 2000 kg / m³. They are used for the construction of walls. The composition of this material includes as a filler light granular products, as well as bulk materials, for example, perlite or agloporite.

The third type in this category are blocks of cement-sand mixture, reinforced with steel mesh or wire mesh with a diameter of 6 mm. Manufacturers offer two versions of this material: hollow and corpulent. It should be noted that blocks of this type have the same strength as products made from heavy concrete, but they are several times cheaper. Therefore, when the question is raised, of which blocks it is better to build a garage, then in this category it is better to give preference to cement-sand.

Slag blocks

A huge brick deficit preceded the appearance of cinder blocks. It was not enough all the time, especially in private housing. Therefore, it was decided to start mass production of this wall building material with the addition to the cement mortar of the so-called waste filler, which was supplied almost free of charge. These were slags from blast furnaces and thermal power plants that operated on coal. Slag is useless material and is difficult to dispose of. The appearance of the production technology of slag stones solved two serious problems at once.

It should be noted that today, under the concept of cinder blocks, they produce and sell piece wall material with different fillers. That is, slag will not necessarily be used in it. Instead, sawdust, shell rock and other cheap ingredients are added to the solution, which primarily reduces the weight of the finished product. But at the same time, the strength of the material is not lower than blocks of lightweight concrete.

On our site you can find contacts of construction companies that offer construction services of small architectural forms . Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

The popularity of cinder blocks is huge. They are still used in low-rise construction, as the main building material for the construction of walls. Depending on the type of filler used, cinder blocks have different characteristics:

-

density from 750 to 1500 kg / m³;

-

thermal conductivity 0,027 to 0.65 W / m K, compared to a brick - 0.8 W / m K;

-

compressive strength corresponds to the materials of the brand from M35 to M150;

-

the service life is up to 100 years, if we take into account the negative impact of natural loads, if the house roof is durable and reliable the house from slag stones will serve not less, than brick.

It should be added that this wall material has its disadvantages:

-

unpresentable appearance ;

-

moisture resistance is not the highest;

-

the difficulty of fastening interior objects to walls built of cinder blocks.

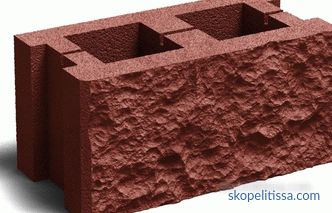

But this material keeps its popularity firmly.The reason - the low price, plus ease of installation. We also add that today manufacturers offer cinder blocks with one decorative side. The original approach to solving the problem of decorating buildings.

It might be interesting! In the article next read the link about construction of a garage in Moscow, the price for turnkey work .

Expanded clay

Wall insulation has always been given special attention. And although for many garages this is not fundamentally important, blocks with the addition of expanded clay are no less popular today than with filler in the form of slags. Their main distinctive feature is low thermal conductivity within 0.14-0.65 W / m K. The difference in performance is quite large, it depends on the amount of cement applied to the solution. The larger it is, the higher the thermal conductivity of the material.

Today, manufacturers offer two types of blocks made of expanded clay concrete:

-

structural , of which walls are constructed;

-

heat-insulating , which are used to insulate buildings.

We are interested in the first option. Here are its specifications:

-

specific gravity from 600 to 1800 kg / m³;

-

strength 35 to 500 kg / cm²;

-

frost resistance - up to 500 cycles;

-

water absorption - up to 10%;

-

temperature limit from -180С to + 1050С;

-

sound insulation within 50 dB;

-

vapor insulation within 0.4.

Blocks for a keramsit concrete garage are now increasingly being used in the construction of garages. Many car owners began to realize that a dry and warm garage is a long-term operation of the car without the formation of corrosive areas on the body.

It may be interesting! In the article on the following link read about choice of paintwork materials for painting the garage .

Blocks of cellular concrete

This building material got its name only because its structure is a solution filled with voids (cells). Today this type of piece wall article on the roar is represented by two positions: foam and gas-concrete blocks. Accordingly, they are made of foam concrete and aerated concrete. Consider their differences from each other.

So, foam concrete is a standard concrete solution to which special substances are added (organic or synthetic). They are called foaming agents. That is, when in contact with water, substances begin to form foam. Inside the solution, small bubbles with air are formed due to the foam. The solution is poured into molds, where it turns into stone. And the air remains so inside, making the structure of the material porous.

The video shows the production of foam concrete:

Aerated concrete is produced using a completely different technology. Firstly, lime and aluminum powder are added to the concrete mortar. Interacting with each other with the participation of water, both substances enter into a chemical reaction in which hydrogen is released. So it forms bubbles inside the mixture. But a chemical reaction can occur only under pressure and with increasing temperature, therefore, aerated concrete blocks are produced in special equipment, which is called an autoclave. Inside, a high pressure is created, and the temperature rises due to the formation of saturated steam.

Also note that foam blocks are material formed in special shapes with the exact dimensions of the final product. Aerated concrete products - a material with large dimensions, which is then cut under the required (standard) parameters. For this string is used. It turns out that foam concrete has a structure with closed pores, gas concrete with open pores. Therefore, the second water absorption is much greater than the first. Hence the important requirement for garages erected from gas blocks. The walls of the building must be protected, it can be plaster or any other type of cladding.

As for the density, it is almost the same for the two materials and varies in the range of 300-1200 kg / m³. But at the same time, the durability of gas blocks is almost twice as high, because they are made by autoclave method. Although it is necessary to pay tribute to the manufacturers of foam blocks, they are already offering products, the production of which is established with the help of autoclaves.

And other characteristics:

-

shrinkage at foam blocks - 1-3 mm / m, for gas blocks - 0.5 mm / m;

-

aerated material holds heat better than its opponent, because it has a uniform structure;

-

fire resistance in two types is the same, that is, it is non-combustible materials.

In the video, the specialist talks about the characteristics of aerated concrete blocks, or rather, whether this wall material is afraid of water and wind:

Gas silicate blocks

If all previous ones Since varieties fall into the category of concrete products, this is a completely different material in which there is no cement. Its recipe includes only sand, lime, water and gas-forming fillers. The production process is autoclaved.

What can be said about the characteristics of a gas silicate:

-

density 300-900 kg / m³;

-

pore diameter - 1-3 mm;

-

shrinkage - within 0.5 mm / m;

-

water absorption - 60%;

-

vapor permeability - 0.3;

-

frost resistance - 70 cycles;

-

begins to collapse already at a temperature of + 400С;

-

thermal conductivity 0.12-0.145 W / m K.

As you can see, this material absorbs moisture like a sponge. So you need to think about whether to use it in the construction of the garage. Of course, if you take protective measures, then this structure can also be built from gas silicate. Although it will be safer block.

It might be interesting! In the article the following link read about volume, how to choose a country house for permanent residence: properly prioritize .

How much is each block?

The price component is an important selection criterion. Therefore, the question of which unit is better for building a garage for the price concerns many people who are planning to start building this building.

Manufacturers offer a fairly wide range of wall blocks in terms of their size. To compare prices, we will consider a traditional block with parameters 20x20x40 cm.

-

a concrete block costs 50 rubles. per share (price averaged over the regions);

-

expanded clay - 38-40 rubles;

-

cinder block - within 30 rubles;

-

foam block - 120 rubles;

-

gas block - 120 rubles;

-

gas silicate - 100 rubles.

It should be noted that the price in each group varies greatly. Because the blocks are made from different concrete solutions. This refers to the grade of the material. And the higher it is, the more expensive the final product. It will be correct to say that factory products, and even more so those produced by the autoclave method, are several times more expensive than handicraft material.

You can also add inaccuracy of sizes and uneven faces of blocks made on construction sites or in small workshops. And, as practice shows, the quality of such products is not the highest.

So now, having dismantled all the pros and cons, you can put all the dots over "i" in the subject of our article, namely: what are the best blocks for building a garage to purchase. The ideal option - cinder blocks. They correspond to the strength of low-rise construction, their price is the lowest, these are products with a fairly smooth surface that can not be finished, although, as mentioned above, the market offers blocks with decorative decoration or painted in the whole stone body. According to the thermal insulation characteristics, this material is inferior to its cellular aggregate or filled with expanded clay, but for garages this is not the most important selection criterion.

There is one more characteristic of cinder block, which is inferior to products with a cellular structure. This is the specific weight. That is, it is more, which means that under the slag stones will have to build a high strength foundation. This increases the budget allocated for the construction of the garage. But even this does not stop private developers from using cinder blocks as the main material in low-rise construction.

The video shows how to build a garage out of cinder blocks:

It might be interesting! In the article follow this link read about the top 10 stairs in the Art Nouveau style: difficult in a simple .

Conclusion on the topic

We have offered you information on all the known blocks from which garages are being built today. Allocated one of them as the best option. But this is just our recommendation. Everyone must decide for himself what material to buy.