Any construction is impossible without the purchase of building materials, a significant part of which are bricks or blocks for the construction of walls and floors. You can determine their exact number by calculating the blocks on the house with a calculator. This refers not to ordinary calculating machines or standard applications on mobile phones, but to specialized online services. Consider how the block calculator is used for building a house when counting materials.

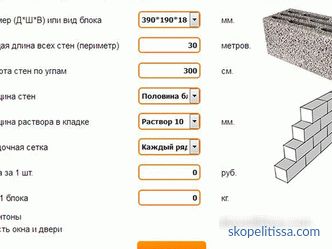

Interface of the online calculator for calculating bricks and building blocks

On the website of the service you need to fill in the fields with the estimated size of the building and the dimensions of the blocks. Then the system will make calculations and produce a relatively accurate amount of stone that will be needed for the construction of a structure with the specified dimensions.

Calculations directly depend on the masonry material used. At the moment there are two main types of it - building blocks and bricks.

The types of bricks

A brick is distinguished by two parameters: the composition of the mixture used for manufacturing and the degree of filling. By combining these two factors, it is possible to obtain material that is suitable for most tasks related to the construction of walls.

The construction industry offers the following options:

Solid ceramic. Due to the absence of voids, it has high moisture resistance and is not prone to freezing. It can be used in structures with high mechanical loads in almost any climatic conditions.

Solid ceramic bricks

Hollow ceramic. It is used for the construction of walls and walls of any types of buildings. In comparison with full-bodied it has a smaller mass and often large dimensions, which allows to speed up the process of wall construction. In addition, voids provide greater thermal insulation with little loss in the mechanical strength.

Hollow ceramic bricks

Silicate. The main material for manufacturing is quartz sand (90%). An aqueous solution of lime is used as a binder. The mixture is pressed under significant pressure. The quality of the product depends on the purity of the material. It should be free of clay, manganese and other polluting substances. Warmer than ceramic. Used for the construction of walls and walls, including multi-storey buildings.

Silicate bricks

Clinker. It can be both full-bodied and hollow. For its manufacture, special grades of clays are used, which are distinguished by high refractoriness and low content of impurities (salts, chalk, some types of minerals). It has a relatively high cost, so it is more used as a facing material.

Klinker bricks in the shop

Hyperpress. Solid brick made by pressing under excessively high pressure . It consists of 90% of screenings, shell rock, marble, dolomite and other minerals that are so rich in open pit mines. The remaining 10% is high quality cement. The brick is more often used for a facing laying. It can be smooth and with a texture imitating a wild stone.

Hyper-pressed brick

On our site you can find contacts of construction companies that offer the service of designing houses. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

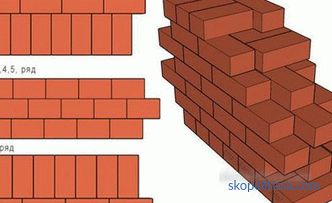

Methods of laying bricks

For a brick calculator to build a house to correctly calculate the number of bricks per house, it is not enough to know its external dimensions. Consumption may vary depending on the masonry that will be used for the construction of walls.

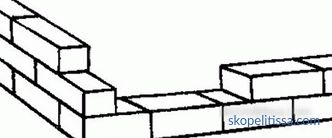

The width of the walls depending on the number of bricks

Bricklaying 0.5 bricks. The process consists in sequentially laying out a brick along its largest plane. Ligation of this design is carried out by placing the stone in a staggered manner.

Brickwork with a half brick

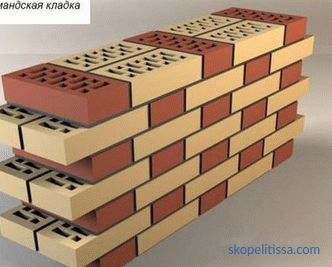

Brickwork with 1 brick. In this case, the brick falls across. Dressing is done in different ways, but basically it is a combination of longitudinal and transverse laying out.

Brickwork in one brick (Flemish dressing)

Brickwork in 1.5 bricks. The total width of the structure is 1.5 brick length. The dressing is formed by changing the position of the longitudinal row.

Brickwork with one and a half bricks

Brickwork with 2 bricks. In this case, the stone falls alternately - a row along and a row across. The total width of the row is equal to two brick lengths.

Two brick masonry

Brick masonry 2.5. One longitudinal is added to the two transverse rows.The dressing is done by changing the location of the longitudinal, as well as using some other methods.

Masonry in two and a half bricks

It may be interesting! In the article the following link read about the calculation of the amount of cement per concrete cube for the foundation.

Calculation of brick at home: the main methods and features of their use

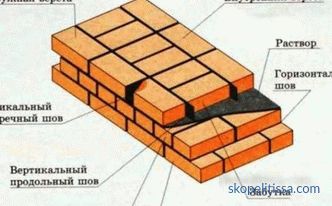

The important point in calculating the required amount of masonry stone are mortar joints. If you do calculations using only the dimensions of a brick, the difference with the actual required amount can reach 30%. This result is obtained because of the relatively large size of the seam, relative to the stone.

Two methods can be used for calculations:

-

The thickness of the seam should be added to the area of the stone and the result multiplied by the total area of the building.

-

Calculate the amount of material that goes to the cube of the structure. Then make calculations for each type of walls and walls.

The second option is considered much simpler and is not inferior in accuracy to the first. In addition to the above methods, you can use the online brick calculator for building a house.

For an example of brick calculation, see the following video:

In any case, you need to make preliminary calculations:

-

The size of the total area of walls and walls, taking into account the thickness, which should be a multiple of the size of the brick.

-

The area of all window and door openings.

-

Recalculate the area of the walls, taking into account the openings.

If you continue the calculation manually, you need to calculate the volume for the walls by multiplying the area by the desired thickness of the structure. Then the result is divided by the volume of brick with mortar seam.

Whatever your mathematical ability, calculations are better to be trusted to specialists who by experience know all the subtleties of working with a stone.

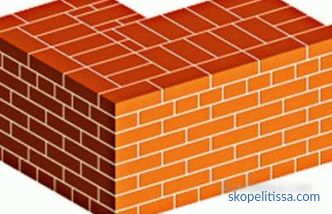

Types of blocks and their use

The use of bricks is not advisable in all cases. Most modern low-rise industrial and residential buildings are erected from wall blocks. The demand for this type of masonry material caused a rapid quantitative growth of its manufacturers, which served to increase the range of block products. The choice is so great that there are no construction problems that cannot be solved with their help. And in order to make the most correct calculation of blocks for the construction of a house, the calculator will require information on the type and size of the material.

House of blocks with a roundabout floor and attic

Wall blocks are artificial and natural. Natural is obtained by developing and giving the necessary form to such rocks as limestone, rakushnyak, granite. Artificial, in turn, are distinguished by the materials and technologies used in the manufacturing process. In modern construction, blocks on concrete base are very popular.

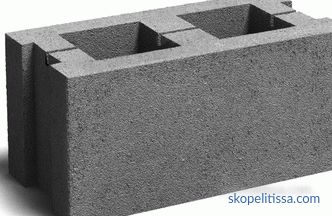

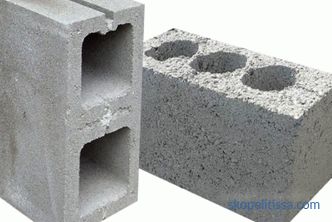

Concrete blocks. The composition of the mixture used for manufacturing includes cement, sand, screenings, crushed stone. Some brands may be reinforced with reinforcement. There are monolithic options and with voids or technological openings for laying communications. Used for the construction of walls and foundations.

Standard concrete block

Ceramsite concrete. In addition to the standard components for concrete (sand, cement, screenings, crushed stone), lightweight aggregate is added to it - expanded clay. The blocks manufactured in this way have high thermal insulation qualities in comparison with concrete variants. At the same time, the strength of expanded clay concrete is sufficient for the construction of a two or three-story house. Used mainly for laying exterior walls, but can be used for walls.

Lightweight blocks of expanded clay

It might be interesting! In the article on the next link read online calculation of the tape base of the house.

Polystyrene concrete. As the name implies, polystyrene is added to the concrete mixture of these blocks, more precisely polystyrene balls. As a result, the product has less weight, more thermal insulation, but less strength. Despite this, some brands of polystyrene blocks are considered to be self-supporting and have no height restrictions. It is used for external and internal laying of walls and walls, as well as insulation.

Polystyrene concrete blocks

Gas silicate. Lightweight unreinforced cellular concrete blocks. Produced in the form of slabs and rectangular stones. The process is of two types: autoclave and non-autoclave. Products made by the first method have enhanced strength characteristics. Used for the construction of walls and walls mainly of residential premises, with a height not exceeding three floors.

Gas silicate building blocks

Foam concrete. Porous concrete blocks with high thermal insulation qualities and low weight. The strength is much inferior to concrete and especially reinforced concrete. Used for the construction of walls and walls. It must be finished to avoid contact with moisture (due to its porous structure, foam concrete is highly hygroscopic).

Building blocks of foam concrete

Calculation of the number of building blocks

Before doing the calculation of blocks per house you need to decide on the project of the future structure. It is important to know the number of doors, windows, the length of the perimeter and the total length of the walls. Considering that the external walls and the walls will be made of different materials, their dimensions should be considered separately. If all these data are known accurately, calculating the number of blocks for building a house, the calculator will produce the most close to real figures.

As a result, two areas should be obtained - external walls and walls (in case of using blocks for the foundation, one more will be added). You can get the numerical values of these areas by simply multiplying the length and width. The final result will be clear after subtracting the area of the door and window openings.

Further calculations depend on the desired thickness of the structural elements and the block material to be used.

Varieties of aerated concrete blocks by size

The technology for calculating the number of gas-silicate blocks

The dimensions of this masonry material vary depending from the place of use. For example, blocks with a width in the range of 200-300 mm are more suitable for internal partitions. While for bearing structures, a width of 400 mm and above is recommended.

Knowing the overall cubage of the walls, the dimensions of the masonry material with an allowance for the seams, the calculation is reduced to purely mathematical operations. Using the calculator blocks for building a house, you can speed up the process of counting the right amount of material.

An example of calculating blocks for a gas-concrete house in the following video:

It might be interesting! In the article on the following link read about the calculation of siding.

Conclusion

Independent calculations, as well as calculations, a construction calculator for calculating walls of blocks or bricks will show only an approximate picture in order to at least slightly present the upcoming expenses. If it comes to the purchase of material, its quantity should be determined by a specialist. Otherwise, at best, you will have to buy more, at worst - to think about what to do with the remnants.