The subject of the article is a rectangular drain. We will talk about why such drains are used today, their advantages and disadvantages, the method of production, as well as the materials from which these products are made. Immediately, we note that the drainage system is an indispensable attribute of a private house, whose function is to divert rain and melt water from the roof so that it does not fall near the foundation and does not fall on the walls of the building in the form of splashes.

Distinctive features of a rectangular drain

It makes no difference what drain is installed on house. This refers to a round or rectangular section. Both variations easily organize the removal of precipitation, provided that the elements of the system were correctly selected by section and the installation was carried out competently.

Just for some private houses, in terms of architectural filling, it is the square or rectangular gutters that look better. Therefore, they are present on the market as a special variety. But there are rectangular elements of the drainage system and another distinctive feature - this is a kind of installation method. That is, the process itself, as well as the sequence, seems identical to the installation of a system with a circular cross section of elements. But there are certain features. Which ones:

-

Tilt angle gutters of the drainage system with rectangular section - 2 , 5 °. This is an ideal parameter, although deviations of half a degree are acceptable. For a system with round section , the angle of inclination varies within 2-7 °, because it is easier to move along the rounded shape of the gutters .

-

Connect gutter elements of drain with self-tapping screws or rivets , which are screwed into lateral parts of the structure. In this case, the junction of the two elements is lubricated with silicone sealant . Docking conducted overlapped with an offset of 5 cm.

-

Tubular elements of the gutter system, the length of which is standard and is 1 m , connect the bell-shaped method followed by crimping. An additional use is for fastening riveting , plus using sealant to completely seal the joint.

-

Fasteners e pipes of the drain to the wall of the house produce clamps every 1 m, that is, at the junction points of pipe riser elements.

For all other positions, the installation of a drain with a rectangular section of its elements is no different from a round one.

Material for the manufacture of rectangular drainage

You will not find a PVC drainage system with a rectangular cross section on the market. This is due to the technological difficulties of forming a rectangular pipe from plastic. That is, it is technically possible to do this, but the cost of technology will be more. So, the price of the product will also increase.

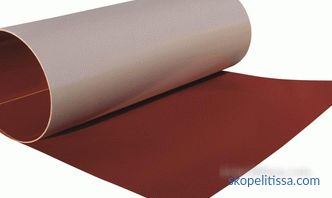

Therefore, there is a drain with a rectangular cross section made of metal only on the market. Or rather, from galvanized steel sheet with a thickness of 0.35-1.2 mm. And the thicker the sheet used, the more expensive the finished product. In the end, either drained gutters, or coated with a polymer composition, come out of production. It is clear that the latter are higher in price, but their service life is longer, provided that the polymer layer was not damaged during transportation and installation.

Today, manufacturers use galvanized steel sheets treated with different polymer compositions for the production of rectangular gutter. Apply the last of different thickness, and therefore the technical characteristics, as well as the life of the drainage elements vary.

On our site you can familiarize yourself with the most popular projects of small forms - bathhouses, gazebos, garages - from construction companies presented at the exhibition "Low-Rise Country".

Here are the polymer compositions that are used to treat steel sheets:

-

Polyester . It is applied with a thickness of 25 microns, it is the smallest parameter, so products covered with this polymer will serve in the open air under the influence of all natural precipitation within 15 years. Add to the information that the applied polymer layer can be glossy or matte. It should be noted that elements made of this material gradually fade in the sun, that is, over time, they lose their presentable appearance.

-

Pural . The basis of this polymer composition is polyurethane . The thickness of the applied layer is 50 microns. Service life - 50 years.Experts note that the drains from this material are the best today, because they have the most ideal technical and operational characteristics.

-

Plastizol . The basis of the composition - polyvinyl (PVC). Layer thickness - 200 microns, service life - 40 years. This is the thickest coating with excellent strength characteristics. But polyvinyl chloride loses them under the action of sunlight. Especially its exterior design look.

-

PVDF . This composition, which consists of two polymers at once: acrylic and polyvinyl fluoride . The ratio of components, respectively, 20 to 80%. This is the latest development, which has high performance. Therefore, apply a layer thickness of only 27 microns. And this is enough to guarantee a long service life - up to 50 years. At the same time, under the influence of natural loads, the polymer layer does not lose its properties and quality throughout the entire service life.

On our site you can find contacts of construction companies that offer the service of drainage and drainage systems, wells, foundation repairs, extensions to existing homes. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Production technology and equipment

The price of equipment for a rectangular drainpipe system is determined by the bundle. The standard kit is:

-

Roll Forming Mill . This is the main type of equipment on which rectangular profiles of the drainage system are produced.

-

Uncoiler . In essence, this is a drum on which a roll of galvanized steel sheet is placed. It rotates, feeding the workpiece to the bending device. Usually the drum can withstand loads up to 2000 kg. It should be noted that the decoilers on the market are represented by different types. For example, cantilever or based on two supports. In this case, it can be volatile units that rotate with the help of an electric motor and a gearbox, and non-drive types can be purchased. That is, the drum rotates under the action of a tensioning device, which is an integral part of the roll forming mill.

-

Cutting device . Its functions include the transverse trimming of galvanized steel sheet (painted or coated with a polymer layer) for standard sizes. And since the width of the sheet roll is 1 m, respectively, the length of the forming elements of the drain will be equal to this indicator.

-

Control cabinet , which controls the entire process, plus sets the parameters of the elements of the drainage system. This refers to the dimensions of the section. The cabinet includes an operator panel.

-

Reception table .

-

The unit , which is used to crimp the pipes and also make taps .

The video shows a square pipe manufacturing equipment:

This could be interesting! In the article on the following link read about the classification of brackets for drainage and the technology of their installation.

The cost of the equipment depends on the capacity of the profile bending mill. For example, you can buy equipment for a rectangular drainage system with a capacity of 30 m / min for 3,000,000 rubles.

It is necessary to add that manufacturers sell all units and devices included in the package separately. For example:

-

A slitting machine costs between 160-180 thousand rubles . The number of knives installed, the thickness of the metal being cut, the power of the installed electric motor, and accordingly the power of the equipment itself are taken into account.

-

A machine for producing a rectangular pipe . It costs up to 400,000 rubles. The price depends on the maximum possible formation of the pipe section, on the thickness and length of the steel billet used, on the production speed.

-

A bending machine on which taps (elbows) are made. On average, this type of equipment costs around 200,000 rubles. The cost depends on the thickness of the formed workpiece, the length of the knee, performance.

-

The machine on which the channels are made. The price component is influenced by the same criteria and characteristics as the pipe manufacturing machine. The average price of the unit - 220,000 rubles.

As practice shows, small companies usually purchase equipment separately, organizing mobile small workshops, which employs up to 4 people. With proper organization of labor, such small-scale production quickly pays off.If the equipment is licensed, then the quality of products will comply with state standards.

It may be interesting! In the article on the following link read about building a new house in the place of an old one: what to do, what documents to collect, nuances of a new construction site.

Advantages of rectangular drains

The advantages of this type of drainage systems are mainly based on the cross-section of profiles.

-

Presentable unusual appearance . As the designers say, such gutters were used on the buildings of the early twentieth century, stylized as modern.

-

The capacity of square and rectangular drain elements is higher than that of round models. Because the size of a circle inscribed in a square is smaller. For example, if the pipe diameter is 87 mm, then the area of the circle is 5942 mm². The area of the square in which the circle of this diameter is inscribed will be 7569 mm². This is almost 30% more. And this is just a ratio of a circle and a square. And given that the rectangle in size is always larger than a square, respectively, he and the area will be larger.

-

With the same dimensions cross-section rectangular drain is by 10-20% less than . Metal consumption is less than .

-

In winter, rectangular gutters and pipes withstand loads from expanding ice better than round ones. It's all about the corners of a rectangular and square design. That is, the freezing water, turning into ice, first fills the corners, and then the rest of the space. From here and decrease in loadings.

The video shows a Finnish production line for a rectangular gutter system:

This could be interesting! In the article on the following link read about sitting high - I look away: a house with transparent walls on the rocky shores in Norway.

Conclusion on the topic

Before deciding which drain to choose a section, determine the design of the house itself. It may happen that the rectangular shape and does not fit. Therefore, consult with a professional designer or architect.

Rate this article, we tried for you