The subject of the article is a metal profile roof. We will tell about what a metal profile is, what characteristics this material has, what types of roofing are presented in this category. We will tell about the advantages and disadvantages of each type, as well as the technology of covering the roofs with metal profiles.

Metal profile - types and design features

A metal roof has always been considered reliable with a long lifetime, but expensive. Most often in the private house building used faltsevoy roof, consisting of stacked sheets of galvanized steel, which is painted all the time to increase the service life. The construction of a folded roof is not an easy task, for its formation a continuous crate was required, which increased the cost of the roof structure.

Metal profiles for roofs solved many problems. In fact, it is a metal product made of galvanized steel sheet, which in the production process was given a profiled shape. That is, panels with a large number of waves are made from a flat sheet. The latter may have the shape of a trapezoid or a standard sloping wave.

In the construction of the roofing material, the profile serves as stiffeners. In this way, the problem was solved - to increase the carrying capacity of metal roofs. And in this case, the greater the height of the profile, the greater the carrying capacity of the material.

Today, manufacturers offer two types of metal profiles:

-

profiled ;

-

metal tile .

These are two different groups, different in appearance from each other. They have one base - steel galvanized sheet, painted or coated with a polymer layer. The waveform is different, the sizes are very different from each other. Yes, and installation technology is different. Therefore, further in the article we will talk about each species separately.

All about profiled

Let's start with the production of profiled sheet based on the technology of cold rolling of the material in the rolling mill. This makes it possible to produce panels with a length of 0.5 to 13 m. This is a big plus for professional flooring, because it is possible to choose a length of roof covering that would cover the entire length of the roof slope at once. That is, a coating without joints and seams was formed on the roof. And for roofing construction, sealing is the most important indicator.

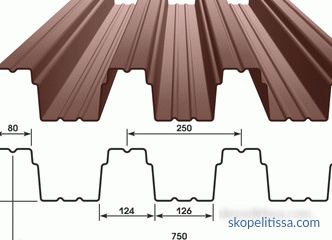

Today, manufacturers offer three classes of corrugated flooring, which differ in their carrying capacity, and, accordingly, in operating conditions.

-

Professional sheet carrier , which is marked with the letter "H". It is most often used in those structures where increased responsibility is required. Therefore, pavilions, ceilings, and protective structures are made of this option. It is often used as a fixed formwork for pouring the foundation. And, of course, for roofing. This material has the highest profile height - not less than 60 mm.

-

Wall decking , denoted by the letter "C". The name of this variety was not in vain. Basically, this model is used for wall cladding. Although we must pay tribute, as on the roofs of peaks, canopies, as well as for the formation of fences, it is suitable. According to the strength characteristics, it is inferior to all the other two. But it is also the cheapest. Profile height - does not exceed 20 mm.

-

The third position is, so to speak, the golden mean, which is why it is called the bearing-wall with the designation “НС”. Excellent performance at a low price make it possible to use it almost everywhere. Its universality was appreciated both by specialists and ordinary consumers, hence the high popularity of the material. Height 35 and 44 mm.

Of the three proposed options for roofs, it is better to choose "H" or "NA". We add that there is another parameter that must be taken into account when choosing a professional flooring for the roof, this is the thickness used in the manufacture of the sheet. The optimal size is 0.5 mm. It may be slightly thicker or slightly thinner, but this parameter is perfect.

On our site you can familiarize yourself with the most popular suburban areas in the Moscow Region houses. In the filters, you can set the desired direction, distance from the Moscow Ring Road, cost per hundred, size, availability of infrastructure, gas, water, electricity and other communications.

Installation of corrugated roofing on the construction of

The installation of metal profiles on the roof, in this case, professional flooring, is made according to standard technology, which is practically no different from a slate roof.That is, the laying is carried out on the crate. And here there is a very interesting pattern - the greater the height of the wave of the roofing material, the less often it is possible to stack the elements of the sheathing. For example:

-

if HC35 profile sheet is selected for roof covering, then battens can be laid in 50-60 cm ;

-

if you use a profiled sheet mark H65 , then the distance can be increased to 1 m ;

-

if the roofing material is H144 professional flooring , then the maximum pitch is 2.5-3 m .

As mentioned above, the wave height determines the carrying capacity of the material itself. Hence the opportunity to save on the crate.

Now about the installation itself. In principle, there are no difficulties here, because everyone is trying to buy sheets of such length that they cover the whole slope by themselves from the eaves to the ridge. But in the transverse direction of the panel is laid overlapping in one wave, thus achieving one hundred percent tightness of the roofing.

On our website you can find contacts of construction companies that offer design and construction services turnkey country houses, roof repair, construction of small architectural forms. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

If for some reason it is not possible to lay solid sheets of metal profiles so as to close the roof without seams and joints, then they use butt technology. Here, as with asbestos slate, laying is carried out with an overlap in the range from 10 to 30 cm. And the smaller the angle of inclination of the roof, the greater the amount of overlap. For example, up to 10 °, the optimal overlap is 30 cm, above 18 ° - 20 cm and so on.

Eats another distinctive feature of profiled sheets from other roofing materials - the method of fastening.

-

For fastening use special roofing screws with a hex head. Their package includes a washer from a special polymer composition, which under the influence of natural loads does not change its qualities , it does not deform, does not burst, does not crack.

-

Fasteners only hold into the lower wave .

-

At the eaves and ridge, fasteners products are screwed into each wave , elsewhere through a wave or two .

-

Self-tapping screws should be twisted perpendicular to the plane of the corrugated board, even the smallest distortions are guaranteed leak points.

-

Firmly twist or do not screw in fasteners you cannot .

Be sure to watch the video, which shows how to properly install flooring on the roof of the house:

All about metal tile

This roofing material was invented as a cheaper alternative to ceramic tiles. It is made of the same galvanized steel sheet, but not by rolling, but by stamping. And since the stamp is limited in size, respectively, the metal tile has certain parameters. Namely:

-

length : total 1190 mm, useful - 1100 mm;

-

width : full 500-3650 mm, useful 350-3500 mm;

-

height of the profile: 12-80 mm.

Manufacturers today offer single-row panels, as well as in several rows. The latter is somewhat similar to decking, but still their length is limited to 3500 mm. Since the profile of the metal tile is a shingle, the roofing of this metal profile is different from the roofing structure covered with profiled panels. Or rather, the difference is based on the installation step of the batten elements, which is 35 cm. In some models it may be slightly larger (40 mm) or less (30 mm), but for most models it is.

It could be interesting! In the article on the following link read about 8 nuances of the choice of metal for the roof: thickness and other parameters.

The distance between the sheathing elements is not in vain. The fact is that the metal tile is a material formed under shingles. Accordingly, the length of the shingles and is the main panel width. And the elements of the sheathing are installed so that the material lies on them with the edges of the shingle, which are concave inward. And this distance is equal to 35 cm.

So, if the crate is ready, you can start laying the metal profile on the roof. This is done according to one standard scheme: from right to left, from bottom to top. The panels are laid strictly parallel to the roof sheet in pairs. That is, they mount the lower tile, on top of it another. Then the second in the bottom row, and then the second in the top row.

The most important thing is that the screws are screwed into the so-called mounting bar, located in the upper part of the panel, which is closed by the bar located in the lower part of the tile. And since the shingles of the roofing material are located between the two strips, there will accordingly be a distance of 35 cm between them. That is, the screw will fall directly into the crate. In this case, the top panel closes the fasteners, so they will not be visible on the roof.

We offer to watch a video that shows the installation of metal tile:

It may be interesting! In the article on the following link, read about the consequences of the work of the gray brigades: what to look for when choosing builders.

Decorative qualities of metal profiles

Not long ago, professional flooring was a gray nondescript material. Today it is a huge variety of colors. There are two types of it on the market, this fully applies to metal tiles:

-

shorter than n ones ;

-

coated with polymer compositions .

It is about the second and let's talk more specifically. Manufacturers offer several polymeric compositions, which differ from each other not only by the polymer, but also by the thickness of the applied layer, on which the basic technical and operational characteristics depend.

-

Polyester . Apply it with a thickness of 25 microns. The texture of the applied layer is smooth, corrosion resistance is good, it easily transfers the sun's rays, however, it gradually fades under their action. It tolerates temperature fluctuations, but mechanical resistance is not the highest. From here and short term of operation - 25 years.

-

Polyester matte . Layer thickness - 35 microns. The structure is matte. Under the influence of the sun does not fade, all other characteristics are identical to the previous version.

-

Pural , which is based on polyurethane. Layer thickness - 50 microns. Of all the proposed options - this is the best. The service life of a metal profile covered with pural is up to 50 years.

-

Plastizol . It is based on polyvinyl chloride, also known as PVC. This polymer composition is applied with a layer of 200 microns. It is this thickness that guarantees the highest mechanical and strength characteristics. But there are drawbacks - the protective layer is afraid of solar radiation, under the action of which it loses its color.

-

PVDF . It is a mixture of acrylic (20%) and polyvinyl fluoride (80%). Apply the material with a layer of 27 microns. But even this is not the thickest layer guarantees a sufficiently high performance characteristics of protection. For example, it can withstand temperatures up to + 120 ° C, the polymer mixture in the sun does not fade, it does not crack.

forall This may be interesting ! In the article on the following link read about a modern brick house - a project for the historic district of Denver from the architects of Studio B.

Conclusion on the topic

Summarizing the topic of the metal profile article that is used to roofing, it should be noted that this is by far the most demanded roofing material. Because it combined in an optimal ratio of price and high performance. Add here it is necessary still simplicity of laying and the wide range in respect of decorative registration.