A modern city dweller has a special feeling for wooden houses. The memory of dozens of generations living in wooden buildings must be superimposed on childhood memories of the summer spent in the village. As a result, sooner or later, there is a desire to acquire your own home, and the choice often falls on wooden housing - a synonym for comfort and reliability.

Despite a lot of new building materials, timber remains the foundation of private wooden housing, and houses from profiled timber become a popular option, confidently crowding buildings from classic (with a rectangular profile) lumber and a rounded log.

Let's take a closer look at the issue of building wooden houses from a professional beam, in the framework of this article.

Technological intricacies

The profiled bar owes its name to a complex shape profile (cross section or slice); ordinary material has a standard rectangular (or square) section. Lumber acquires a complex form as a result of the passage of a long production chain, the links of which are:

-

Harvesting . The best material for the manufacture of profiled timber is coniferous wood. Pine and spruce, as a quickly renewable resource, are used most often, and timber from them is cheaper. Larch and oak are resistant to rotting and have a denser, high-quality structure, which is reflected in the price of finished lumber.

-

Sawing . From a harvested log, sorted by diameter, a sawn timber of a given size is cut into a sawmill, with a square or rectangular section.

-

Sort . At this stage, lumber with damage is detected and rejected. Sorted blanks of natural moisture are calibrated by section and length.

-

Drying . It can be carried out in natural conditions, when for several months billets are stacked in piles (which provides airing) - a bar for natural drying. Another, usually more preferable, option is forced drying in hermetic drying chambers for 2.5-4 weeks (chamber drying beams).

-

Processing . Timber is polished and processed on a high-tech machine, where it gets the exact final shape (given profile) and size. The groove of the timber, in addition to creating a beautiful front surface and a thorn-groove lock, reduces the internal stress of the wood fibers - in the future such wood will not “twist” with a seasonal change in air humidity.

-

Packaging . The beam is packaged in shrink film, which helps to keep low humidity during storage and transportation.

Types of profiled timber

Popularity of profiled timber has generated a wide variety of sawn timber offered by domestic and foreign manufacturers. Existing types of timber are classified according to the following features:

-

By size . The length of products varies from 1 to 6 m. A bar with a standard section has parameters of 100x100, 150x150 or 200x200 mm.

-

By the method of drying . Distinguish timber of natural moisture (above 20%, usually up to 40%) and dry profiled timber (according to GOST 8242-88, humidity should not exceed 10-12%).

-

According to the structure . Manufacturers offer a solid product (from the array), warm (double) and glued (assembled from lamellae).

-

By the method of surface treatment . Billets are processed in several ways. As a result, two horizontal (docking) sides get a mirror profile for assembly. Two vertical surfaces (obverse) acquire a flat appearance or remain cylindrical (both or only one). In the latter case, the house of dry profiled timber becomes like a log cabin.

-

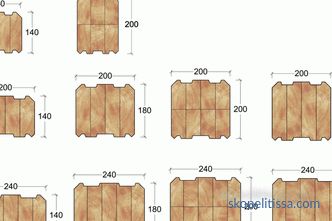

By type of profile . After grooving, one, two or several pairs of tongue-and-groove joints appear on the beam. The last option is a German profile, in the domestic market called "comb". Most of the profiles on the installation technology fit with the use of insulation, and numerous grooves "comb" by themselves eliminate the occurrence of cold bridges, so the use of insulating pads with it is not provided.

Profile views

The profile of the product is arranged according to the system "thorn-groove": on the joining surfaces, crests (spikes) and grooves are cut out according to the pattern, due to which adjacent connections are locked into a lock.According to the geometry of the profile, timber can be divided into several types:

-

Profile with one spike . The easiest and most inexpensive option; Lumber of natural moisture with a single-pointed profile is used in the construction of arbors, outbuildings and baths. Due to the design in the joints is not going to moisture.

-

Profile with two spikes . This timber is suitable for the construction of buildings year-round living. Double spike virtually eliminates the likelihood of cold bridges at the junction.

-

Profile with chamfered . It can be produced with a different number of spikes and grooves, but the chamfer is removed only from the upper edges of the workpiece. This form simplifies caulk walls and does not allow water to flow into the joints.

-

Comb (German) . There are three or more thorn-groove pairs in the construction, due to which adjacent bars fit particularly tightly, are not blown through and do without additional insulation. German profile is most often used in the manufacture of laminated veneer lumber.

-

Finnish profile . It is a two side spikes with beveled chamfers and a flat platform cut between them. A wide platform allows for maximum fit, the heater is easy to lay. This version of the profile is found on the beam chamber drying.

-

Scandinavian . Combines the features of the Finnish and German profiles. High (12 mm) spikes of a trapezoidal cross-section with wide platforms are convenient for drilling holes for dowels. This profile is often equipped with a bar of natural moisture.

On our site you can familiarize yourself with the most popular projects of houses from the profiled timber from construction companies represented at the exhibition "Low-Rise Country".

Strengths and weaknesses of the corrugated beam

Not so long ago, logs were mainly used in country house-building; Today, the construction of houses from profiled timber is expanding. Material is appreciated for its advantages:

-

Favorable price / quality ratio . The construction of dry profiled timber will serve reliably, look stylish, and will cost less than from other wooden material.

-

Technological product . On high-precision equipment, bars are obtained that do not need further adjustment (which cannot be said about handicraft material). The house-made domokoplekt accelerates construction, as it contains all the details required by the project (made according to specified dimensions, numbered and packed).

-

Construction speed . The verified geometry of a profile bar makes installation simple and fast. A professional team assembles a box at home for 1-2 months (the variation of terms depends on the complexity of the project).

-

Low weight . A dry corrugated beam exerts less pressure on the base than a brick building. This allows you to reduce the estimate for the arrangement of the foundation and use any of its varieties.

-

Energy Efficiency . Profile reduces air circulation; the more spikes (crests) in the structure, the lower the thermal conductivity and walls better cope with their heat-shielding function. Lumber with high-quality profiling (manufactured in the factory) does not need a caulker or inter-heater insulation.

On our site you can find the contacts of construction companies, who offer the service of building houses from profiled timber. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

-

Saving size . Technological methods allow to minimize the natural property of wood - cracking and deformation during drying. This is achieved by properly organized drying, and chamber drying better reduces the level of humidity, and natural allows the timber to dry evenly. Another way to prevent gaps is to compensate. The width of the cracks on a quality dry bar is less than 2 mm.

-

Minimum shrinkage . In the first year after erection, the shrinkage of a house from a profiled bar does not exceed 3% of the height of the walls, and subsequently - no more than 5%. Minimal shrinkage reduces the likelihood of cracks between the bars, which in turn has a positive effect on the heat-saving properties of the structure; there is no need for cauldrons (insulation).

-

Diversity . Profbrus resistant to weather vagaries and is suitable for building houses in most climatic zones.

-

Bio-resistance . Chamber drying eliminates wood from mold and bugs; natural drying timber is additionally impregnated with protective agents.

-

Environmental friendliness . A bar with a profile is an array of natural wood that does not obstruct air exchange (up to 30% of room air is filtered per day), which allows maintaining a favorable microclimate. Glued laminated timber loses in this parameter, since its production uses 3 liters of polyurethane or polyvinyl acetate adhesive per 1 m 2 surface.

-

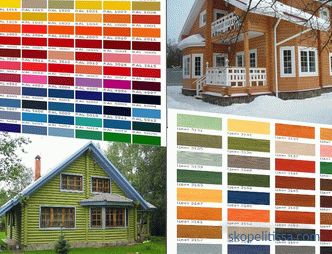

Aesthetics . Wooden walls are one of the most spectacular ways to draw attention to the exterior and interior of the house. Unique design can be obtained without even resorting to additional finishing.

About the advantages of the profiled bar in the following video:

As with any building material, the profiled bar has drawbacks :

-

Disturbance of the geometry of substandard products . A timber obtained with impaired manufacturing technology (most often, drying) may go cracked or deformed.

-

Price . Due to the peculiarities of the production, the bar is twice as cheap as the glued counterpart. But there is a nuance: the facade of laminated veneer lumber can not be lined, and the house of the corrugated beam often requires exterior finish; as a result, the cost of buildings can be equal.

-

Flammability . This is a common shortcoming of all wooden buildings. To reduce the likelihood of fire, it is recommended to soak wood surfaces with fire retardants every 5-6 years. During the subsequent operation of the house, it is necessary to take into account that these compounds only reduce the flammability of wood - that is, when exposed to open fire, the treated wooden surface will still burn, although much later than the untreated one.

It might be interesting! In the article on the following link read about the features of the production and use in the construction of profiled timber.

-

Health Effects . If low-quality (in order to save cheap) impregnation was used to protect the wood, the timber can become a source of phenol, which will certainly affect the well-being of the household. To avoid such a development of events, it is worth working only with proven, reputable manufacturers.

-

Appearance . Natural wood darkens with time. Sooner or later the walls will need tinting and varnishing.

About the construction of a house from a corrugated beam in the following video:

Features of a house from a corrugated beam

To building a house from a bar was not a disappointment, you need to choose the right size of the material. The beam, selected with regard to the peculiarities of the future housing, will show itself well both in the construction of the house and in its operation. When choosing the thickness of the log beam, they are oriented to the purpose and location of the building. The following sizes are mainly used:

-

A bar with a thickness of 100 mm with a double spike is used to build seasonal dwellings (summer cottages); It is ideal for the construction of baths, gazebos, outbuildings and verandas.

-

A bar with a thickness of 150 mm and with a German profile can be used to build housing in regions with mild, short winters.

It might be interesting! B article on the following link read about the house of the bar.

-

Bar 200 mm thick . Classic, repeatedly proven format for the construction of a reliable and comfortable housing without additional insulation.

The house from a dry profiled bar of chamber drying has the following features:

-

When generating estimates . The use of forced drying increases the price of the log by 30%, but makes the shrinkage (and subsequent surface deformations) minimal. The use of profbrus natural moisture will cause significant (and prolonged) shrinkage; housewarming will have to be postponed.

-

Under construction . The design of the timber (thorn-groove connection) shortens the construction time and makes it possible to refuse wall cladding. The technology allows you to create a bar of arbitrary length required for an individual project; however, there is a difficulty in implementing complex projects (misconfiguration).

-

During operation . Bars fit so tightly that there is no reason to worry that water will leak between them and rot begin. Periodically it is necessary to take care of the surfaces, covering them with protective compounds.After construction, the house can not be rescheduled.

It might be interesting! In the article on the following link read about the house from the bar 6x6.

Craft production

In low-rise housing construction, it was the steel bar that became a worthy substitute for classic sawn timber. Its reliable fastenings create a solid wall construction with enhanced thermal insulation properties, which makes it possible to abandon the use of insulation. According to builders, the best quality shows profbrus with a profile-comb. The praiseworthy popularity, unfortunately, has a downside: the release of such a profile is often adjusted in artisanal conditions.

About the house of a profbrus, built 6 years ago in the following video:

Craftsmen, wishing to speed up the process of production of the profbrus, make numerous adjustments simplifying technology and allowing to produce cheaper products. The use of such a "modified" material results in the appearance of defects:

-

At the installation stage . Poor outdated equipment does not allow to cut grooves and ridges exactly in size. When assembling the walls there are difficulties with docking bars. The work is especially complicated when (in conditions of wet weather) wood picks up moisture (and it picks up, as the drying was most likely done with irregularities) and ridges with great difficulty enter the grooves.

-

During the operation of housing . Assembling a house from a profiled beam of suspicious origin causes the appearance of unplanned cracks in wall structures. The ability of the building to keep warm drops sharply, and utility bills begin to grow. The use of material with uncontrolled drying leads to uneven (and often significant) shrinkage and the appearance of noticeable cracks.

Of great importance for a long and happy life at home is not only the quality of the lumber, but also the professionalism of the work team. Perhaps the installers that you hired on an ad in the newspaper, really have solid experience in the construction of wooden houses. Only the workers did not specify (and you forgot to ask) that they were building houses, for example, from laminated timber. This, no doubt, meritorious experience cannot be entirely transferred to the profile bar. Most likely, a lot of mistakes will be made during the installation, many of which you will not know immediately. The only recipe from such a development of events will be an appeal to a construction company that values its reputation and therefore shows sincere concern about the quality of the buildings being erected.

House-complete sets made of corrugated stone

Houses from a profiled turnkey bar rational choice among the technologies of country housing. Reliable, well-developed methodology developed by construction companies, allows you to build projects of different architectural solutions. The cost of domokomplekt in many respects is determined by the price of the professional beam; material cost is determined by the parameters:

-

Type of wood and method of drying .

-

Section . The larger it is, the harder it is to dry the material evenly and the greater the price tag will be on the product.

-

Additional processing . The price is affected by milling (the complexity of cutting the profile) and impregnation with an antiseptic (flame retardant).

The price of profiled building materials is in the range of 8-11 thousand rubles. / m²

The project from a profbruz by the individual order (non-standard configuration) assumes additional difficulties in production and installation that by all means is reflected in cost. In the offer of many construction organizations there is a sufficient choice of ready house sets from a profiled bar. The standard set-designer includes:

-

profiled marked beams made according to the drawings;

-

interfloor and garret logs, truss system, floor and finish floor boards, woodwork;

-

wood processing, communications inputs.

The price of the finished house set is in the range of 12-14 thousand rubles. / m²

Houses from turnkey profbruza: projects and prices

If you need a project of a house from a profiled bar, the price of which will be the best way to reflect its quality, use the services of a construction company with many years of experience in this field . You will be offered both standard wooden houses, and individual design (if there was no suitable option).The latter option makes it possible to order a project in any style you like. The choice of architectural solutions is varied; most often customers stop at a project in a classic, modern or minimalist style, less often - in ethnic, retro or high-tech.

Many companies offer customers to independently follow the pricing, providing a preliminary estimate. You can, combining options (type of foundation and roof, lumber cross-section, the amount of finishing), buy a house that fits into the allocated budget.

The price of a house for year-round living (a 200 mm thick beam) with an area of approximately 100 m² is:

-

Basic set for shrinkage: 1.2-1.8 million rubles.

-

The same house turnkey: 2.2-3 million rubles.

Average prices for country houses from a turnkey profile bar (Moscow region) are presented in the ranges:

-

Houses with an area of up to 100 m² : 2.1-3.4 million rubles.

-

Area from 100 to 200 m²: 2.8-4.1 million rubles.

-

From 200 to 300 m²: 4-5.5 million rubles.

It might be interesting! In the article on the following link read about building a house from a bar.

Conclusion

Profiled timber has proven itself well in Europe and America, and it leads the domestic private housing market. The technology of the material, the castle joint of dried bars, makes it possible to successfully apply it in the construction of houses located in harsh climatic zones with long frosty winters. And if you know about the flaws of the material, you can always take them into account and minimize.