For low-rise private construction, the choice of material is paramount. The future owner seeks to find a balance between the price, quality and timing of the construction of housing. In many cases, a concrete block house is a reasonable alternative to classic brick and wood.

The widespread use of aerated concrete in construction began relatively recently. Rapid, ubiquitous distribution inevitably runs into distrust, a natural human reaction to everything new. Construction companies, offering to build a house of aerated concrete, are guided by the preferences and wishes of customers.

Aerated concrete walls reliably resist frost

Country house of aerated concrete - material features

Although building a house of aerated concrete blocks will seem like a simple job to many, it is necessary to have the knowledge and skills to get a guaranteed high-quality result.

A little about aerated concrete

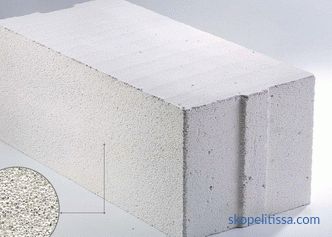

Aerated concrete is an artificial stone belonging to the family of cellular concrete. It has a structure, a characteristic feature of which is the uniform distribution of interconnected pores.

Aerated concrete is produced from a mixture of cement, silica sand, additives (gypsum, ash) and a blowing agent (usually aluminum powder). After mixing, hydrogen gas begins to be released, forming numerous cells (up to 85% of the volume) and ensuring the lightness of the material. To make aerated concrete strong, it is treated with water vapor in an autoclave (autoclave version) or exposed to high temperature in an electric drying chamber (non-autoclave).

Country house of aerated concrete: advantages

-

Lightness of the material. Allows significant savings on transportation and construction work; do not weigh the foundation, which is especially valuable on unstable ground. Special equipment during the work is not required.

The block structure effectively retains heat

-

Durability. The structure of the stone, obtained under the action of temperature and high pressure, allows the construction of buildings up to 5 floors high.

-

Easy processing. Comparable with a tree; blocks are easily sawn and drilled. Large dimensions and precise shape facilitate installation, reducing the cost of work.

-

Refusal of masonry (cement) mixture. It can be replaced with a special adhesive that reduces heat loss by 8-10%.

-

Construction speed. Increased due to the lightness and large size of the blocks.

-

Environmental friendliness. Only natural non-toxic ingredients are included.

-

Incombustible. A wall of gas blocks can withstand open fire for 4-5 hours.

-

Thermal insulation. The material retains heat well due to its porous structure.

Disadvantages

-

Problems with fasteners. In the porous structure, standard dowels and nails do not hold well, the wall material begins to crumble. For reliable fixing it is necessary to use fasteners specially designed for porous surfaces: metal, nylon, plastic or chemical (on the basis of glue).

Dowel for mounting in aerated concrete

-

High hygroscopicity. Aerated concrete is able to absorb from the external environment and accumulate moisture, increasing its weight (sometimes by 25%). The consequence is that the insulation deteriorates dramatically, the material begins to deform and collapse. A preventive measure can be surface treatment with water-repellent impregnation. The procedure should be repeated every 2 years, this increases operating costs.

-

Wall thickness. In the Moscow region, turnkey aerated concrete houses, projects and prices of which are adapted to local conditions, should have a wall thickness of 65 cm. -12%).

-

Cracks in the walls. It may appear both on the blocks and along the line of masonry if the foundation begins to shrink and the solidity of the structure is broken.

Lifetime of aerated concrete house

The first buildings of aerated concrete (and foam concrete) began to appear in Europe and America after World War II, mass construction began 35-40 years ago . Manufacturers claim that the service life of structures built from foam and gas blocks is about 80-100 years, if after 60 years of operation was overhauled.

Service life - a function of many variables

On our site you can familiarize yourself with the most popular projects. aerated concrete houses from construction companies presented at the exhibition "Low-Rise Country" houses.

Therefore, the issue is considered premature, although it is clear that the building may serve less under the influence of some factors:

-

Load change. The design laid the strength of the foundation and frame of the building. It should take into account the excess load (for example, with increased seismic activity).

-

Masonry errors. Poor cement mortar or its incorrect thickness redistributes the load inside the wall, which leads to the appearance of microcracks and reduces the strength of the wall.

-

Frosty winters. Annual cycles of freezing and thawing lead to accumulation of microdefects in blocks, which is why the strength of the walls suffers.

The aerated concrete structure is able to serve the stated period if:

-

the house is built according to a professional project, with correct calculations of the load-bearing structures , soil and climate);

-

construction technologies were implemented;

-

operating conditions were met.

Finishing the facade with brick protects the walls from damp

How to ensure durability of the house of aerated concrete

Ways to help extend the service life:

-

External protection of walls. Unprotected aerated concrete cannot resist weather factors: it readily absorbs moisture, which fills the voids of the material. After the first frost, the water turns into ice, which expands and begins to gradually destroy the outer layer of the wall. The outer facing (plaster, tile or facing brick) and the device of the ventilated facade (protection of the surface considerably increases) serve as protection from the scourge.

-

Foundation Device. Calculated with errors, the sagging foundation will affect the strength and durability of the structure not in the best way. To prevent shrinking deformations and the risk of massive cracks in the masonry, a monolithic strip foundation is arranged. This is one of the many reasons why the construction of houses made of aerated concrete should be carried out by experienced professionals.

-

Structural reinforcement. When erecting buildings with 2 or more floors, the frame is reinforced with a reinforced belt on each floor.

The rules and regulations for the erection of buildings made of aerated concrete are spelled out in SNiP and GOST documents. Their implementation, as well as thoughtful operation can extend the life of the building for a period determined by the manufacturer.

About how blocks are made and their stamps in the video:

Erection houses made of aerated concrete: an error or a reasonable choice

If you have decided to build a house, but have not yet decided on the material, take a closer look at the aerated concrete. Among all the materials used in modern private construction, perhaps, it is aerated concrete surrounded by many conflicting judgments. Among the disputes about quality, a simple truth is somehow forgotten: each material is endowed with a number of features; ignoring them and, therefore, misusing them inevitably leads to frustration.

Aerated concrete walls reduce heating costs

On our site you can find contacts of construction companies, who offer the service of building aerated concrete houses. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

The demand for houses built of aerated concrete has been growing steadily over the past decade. Having decided to build a house of aerated concrete, the customer does not donate either the level of heat saving, nor the microclimate, nor the general quality of the building. The walls of aerated concrete blocks confidently resist the harsh Russian winters, while maintaining the warmth and comfort of the family hearth.

For many customers, an important question is saving, the best answer to which is a house of aerated concrete blocks:

-

Finance savings during the construction phase. Reasonable prices for the construction of turnkey houses made of aerated concrete make this method particularly attractive.

-

Save time. It will take 5-8 months to erect an aerated concrete house, including the laying of utilities and interior decoration.

-

Savings in operation. Thanks to its brilliant thermal insulation qualities, aerated concrete walls can significantly reduce heating costs.

Walls at the stage of insulation

About the construction period

The timing is influenced by such parameters as the area of the building, the type of foundation and roof, the complexity of the installation of communications. A guideline can serve as intervals:

-

Construction of the foundation - 1.5-2 months.

-

Walls and floors - 1-2 months.

-

Installation of the roof and roof can take from 2 to 4 weeks (the design can be complex - multi-skid or multi-level).

-

Installation of windows and doors - up to 10-15 days.

-

Electrical installation - 8-15 days.

-

Distribution of engineering networks (water supply, sewerage, heating) - 25-30 days.

-

Finishing - 2-4 months.

The cost of building a house of aerated concrete

Construction companies offer the construction of houses of turnkey aerated concrete, projects and prices which allow any customer to find a suitable option. A company building your home will develop a project for free.

Proposals attract with simplicity of assembly, weight of design decisions and democratic cost for building a house made of aerated concrete. The price in the Moscow region can be within the following limits:

-

Up to 120 m 2 . Proposals in the interval 2.65-3.7 million rubles.

-

120-160 m 2 . The range is 4.2-6-6 million rubles.

-

160-200 m 2 . Cost between 4.4-5.2 million rubles.

-

From 200 m 2 . Construction will cost 5.4-7.2 million rubles.

A house made of gas blocks, the classic color scheme

This may be interesting! In the article on the following link read about the projects of townhouses.

How to save on building a house of aerated concrete

Saving in construction often turns into a personal test of the proverb that the miser pays twice - to build a house from a gas key, and the price is relatively high, at a lower cost often leads to serious problems during the period of operation. The most common types of errors are:

Purchase of materials

In order to really save money, you will have to spend no less time than on construction work and do it ahead of time to make the next stage of construction got up. Such a pace is exhausting and brings a fair amount of chaos, since the cost in the market or in the online store can vary by 150-200% in any direction.

About how a house is made of aerated concrete on video:

Delivery and unloading

Can fly into a pretty penny, if these works are not included in the total estimate. But this is not a panacea - expensive delivery of cheap material often puts an end to savings. Another underwater stone - access roads to the construction site. You may have to choose between one-time laying of road slabs or regular (with every supply of materials) payment of the manipulator.

Workers

Difficulties arise, even if you have signed a contract with the workers, including deadlines and rates. It is impossible to foresee and protect everything from sudden expenses, without experience. If when signing a contract for the construction of a turnkey aerated concrete house, the projects included the installation of the roof system and the roof, but the insulation was not prescribed, it will inevitably have to be paid extra.

Also, do not look for a universal brigade - it is unlikely that bricklayers will intelligently reconstruct the electrical wiring or install plumbing. This means that it will be necessary to select several qualified teams, which makes the process much more complicated.

Finishing of the facade with siding

Conclusion

Independent construction inevitably stretches in time and incidentally spoils a huge amount of material. It will take time, nerves and finances to correct the mistakes made; otherwise live with them for decades. To get a guaranteed high-quality result, you should entrust the construction of a house made of aerated concrete to the profile company, and leave yourself the role of an interested observer with the right to vote (and control).

The advantages of working with a construction company

Gas-block houses, the projects and prices of which are agreed with the customer, are not inferior in comfort to brick counterparts and are suitable for year-round living in areas with snowy and frosty winters. Cooperation with a construction company involves a lot of pleasant nuances:

-

the cost of construction is fixed in the contract and does not change anymore;

-

if an organization undertakes construction, an individual the architectural project is developed free of charge;

-

the customer receives an estimate and legal documents drawn up by a lawyer in the respective organizations;

-

the company purchases materials on its own; The work is carried out by bricklayers, dressers, plumbers and gas welders with extensive practical experience.

House built by the construction company

Features of some stages of building houses from aerated concrete blocks

The main feature is the need for additional protection of walls from moisture. This allows you to maintain high thermal insulation properties of the material.

Foundation

Although aerated concrete is lightweight, it is not recommended to underestimate the cost of the foundation, it can turn into cracks in the walls. With any construction on the arrangement of the foundation takes about 20% of the total amount. If a boiler room or garage is planned in the basement, the budget will increase.

Walls, floors and roofing

For walls to be strong, they are reinforced (reinforced). Reinforcement is subject to the first row, and then every fourth. For this, the laid row is gouged (grooves are laid). The fittings are laid in the grooves, which are then poured with concrete. Reinforcement perform around the window and door openings. The overlap can be reinforced concrete or on wooden beams (if the area of the house is small). There are no restrictions on the choice of roofing, the customer chooses it at his discretion.

What is aerated concrete? What are the pros and cons? See in this issue:

Exterior and interior finish

When choosing materials, the following rules are observed:

-

vapor proof materials are used for exterior decoration;

-

for interior decoration - vapor permeable.

If you break this rule, the advantage of aerated concrete houses disappears: the effectiveness of thermal insulation drops sharply, and the walls lose the ability to "breathe." For exterior wall decoration choose:

-

plaster mixtures intended for aerated concrete walls;

-

facing brick;

-

facade decorative plasters with a warming effect; the wall is pre-primed;

-

ventilated facades.

Aerated concrete house ready to move in

History of use of aerated concrete is not boasts of its duration. Despite this, the properties of the material, its availability and subsequent economy in the operation of the building become decisive factors for the increasing number of people every year.

It may be interesting! In the article on the following link read about MLC technology of frame houses.

Conclusion

Having ordered the construction of a cottage from turnkey aerated concrete, you can not worry about the quality of any stage of work, research, design, construction, finishing or engineering. Construction will be carried out in compliance with the technology and regulations, under the close supervision of specialists of the company.