The article focuses on the metal profile garage. We will talk about what material can be used in the construction of the garage frame, about the technology of connecting elements and the metal profile itself, how to carry out the construction calculations correctly, and whether drawings are necessary for this. If someone decided to use this particular garage structure for the car, then the information provided will be very useful.

What is metal profiles

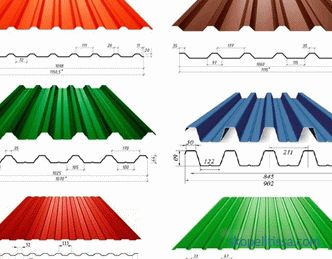

Let's start with this, that is, with parsing, What is this building material? This is nothing more than a corrugated sheet made of galvanized steel sheet, painted or unpainted, or treated from above with a polymer layer. They make profiled sheets of coiled steel, so in the workshop it can be cut for you to any length, which simplifies the installation process and makes the garage facing without joints and seams.

Today the professional flooring on the market is represented by a serious variety. But it is divided into three main groups:

-

wall marked "C";

-

bearing - "Н";

-

universal - "НС".

When talking about a garage from a profile, preference is given to either the "C" or "NA" brand. It is very important to pay attention to the height of the wave. For a garage building, select sheets with this parameter not less than 20 mm. As for the thickness of the material used, the optimum is 0.45-0.5 mm.

So, we got acquainted with the metal profile, go directly to the rules for the construction of the garage.

Garage construction technology from metal profiles

First of all, they determine the location garage built. There are several positions that need to be taken into account. They are advisory, but practice has shown that they are not in vain.

So:

-

from the garage to the windows of the main house on the adjacent plot, you must leave a distance of 6 m;

-

to the windows of your own house - 3 m;

-

you can not build a garage on the section through which the communication networks pass from they should be erected at least at a distance of 1 m;

-

if a garage is being built with an adjoining to the main house in the suburban area, then acoustic insulation measures will have to be taken and roofs;

-

a free path should approach the garage construction , optimally - direct from the entrance gate to the site.

Marking the area for a garage and building a foundation

The dimensions of the garage itself are laid in the basis of the marking. For one machine, a 4x6 m variant is suitable. These parameters are transferred to the ground, where they are marked with chalky sprinkling or by installing pegs with strapping with string. Here it is important to establish the correctness of the angles, which are checked by measuring the diagonals of the rectangle. If both sizes are equal, then the rectangle has right angles.

Now for the foundation. Frame garage of metal profiles - the structure is not heavy. Therefore, it is optimal to fill the slab foundation, which will additionally serve as a floor base, perfectly supporting the weight of the car.

But this option can only be used if there is no basement under the garage. If the latter is present in the project, then you will have to fill in or assemble the strip foundation with the laying of reinforced concrete slabs on it. As a second option - pour monolithic reinforced slabs.

There is a third option - the installation of a frame structure on piles. It is usually used on sites with mobile soil. In this article we will tell you how to fill the slab foundation under the garage. We will not be deeply rooted in the nuances of the process; we simply denote the sequence of main operations.

-

Dig a ditch with a depth of 30- 50 cm on the markings on the ground.

-

Make crushed stone, and then sand bedding . The thickness of each layer is 15 -20 cm. Each layer is aligned with the horizon and rammed.

-

Lay waterproofing . This may be a rolled material, for example, a ruberoid or hydroisol. Laying is carried out in two layers with an overlap of stacked strips of waterproofing material in the range of 10-15 cm. Lay the layers relative to each other in perpendicular directions.

-

On the stands, install a reinforcing frame made of steel reinforcement in the form of a lattice with cells of 20x20 cm. When installing the grate from its edges to the edges of the pit, gaps should remain - 5 cm.As supports, you can use bricks, stone or metal profiles: angle, pipe, channel, and so on. There are on sale special supports from plastic or steel.

-

Fill the prepared trench with a concrete solution of a grade not lower than M300. It must be tamped to remove air.

On our site you can familiarize yourself with the most popular projects "small forms" for a private house - from construction companies represented at the exhibition of houses "Low-Rise Country".

If a part of the foundation structure protrudes beyond the soil, then a formwork made of planks is installed around the perimeter of the excavation. The main thing - just pick them in width, which determines the height of the formwork. After 7 days, the formwork is removed, after another 10-15 days the foundation can be loaded.

If there is an inspection pit in the garage, then it is dug up before starting the formation of the foundation. That is, until the foundation pit is filled up with the above indicated layers of different building materials. It is necessarily formed by walls made of bricks or concrete blocks and the floor of concrete solution.

The frame of the garage

The frame of the garage of a metal profile can be metal or wood. In the first case, it is either a corner or a shaped tube. In the second - this is sawn timber in the form of beams, which, prior to the installation of corrugated flooring, are necessarily treated with an antiseptic composition. In the photo below, a wooden frame garage is shown if someone doubts that such constructions can be used. Collect frame construction directly on the finished foundation.

How to assemble the metal frame

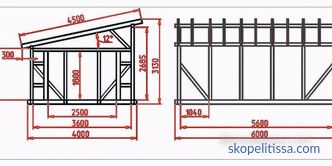

Before starting the construction of the frame, you need to sketch a primitive drawing of the garage from a metalprofile with sizes. Since the dimensions of the perimeter are known, it remains to choose the height of the structure, as well as to determine the type of roof. For such buildings, the roof is usually represented either in the form of a single-pitch construction, or in the form of a gable. As for the height, the minimum size is 2 m.

Therefore, several segments are cut from a steel corner or a profile pipe:

-

4 pieces of 6 m ;

-

4 pieces of 4 m ;

-

12 pieces of 2 m .

This is enough for a start. First, two rectangles are assembled with dimensions of 2x4 m. The method of connection is electric welding.

They are set along the edges of the slab foundation longitudinally from each other. Connect two farms six meter lengths at the bottom corners and at the top. Since the six-meter length of a pipe or a corner is large enough, this may result in slackening of profiles installed along the top trim. Therefore, immediately during the installation process, they are supported by two-meter elements, evenly spaced in 1 m steps.

On our website You can familiarize yourself with the most popular sites in Moscow Region for the construction of a country house . In filters you can set the desired direction, the presence of gas, water, electricity and other communications.

Basically, the box is ready. It remains to collect the roof. If it is single-pitch, then small sections of the profile used are welded along one side of the frame along the top trim. Their length depends on the angle of the roof. The installation step is 1 m. They are tied along the upper edge with one profile.

Then cut the segments, which will be used as rafter legs. To do this, it is necessary to take measurements from the installed upper truss, which forms the angle of inclination, to the opposite part of the upper trim of the garage frame. In addition to the parameter obtained, add 30 cm on each side of the building to the overhangs. The segments cut by the obtained value are welded as a roofing structure every meter.

The photo below shows a drawing of a garage with a single-pitch metal-roofed roof, in which the roof with the size of the overhangs is clearly visible.

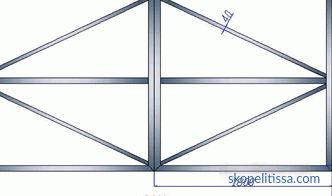

If you plan to install a gable roof above the garage, you need to make triangular trusses, which then installed on the garage box with a pitch of 1 m. They must be connected to each other with two or three additional elements for each ramp. These sections of the profile are laid across the trusses, which are fastened by welding.

How to assemble a wooden frame

In principle, the assembly technology of a wooden frame is almost exactly the same. A distinctive feature is the method of attaching lumber to each other. Today, this is done with perforated steel fasteners and screws. The photo below shows how you can interconnect the lower trusses.

It should be added that the wooden frame for the garage is not going to separate elements: trusses and other structures , and separately with the installation of each element at its destination. On the one hand, it simplifies the assembly process. On the other hand, each element has to either hold or install supports under it until it is firmly fixed with the neighboring element.

It might be interesting! In the article on the following link, read about what materials are used to properly block the roof of the garage .

Sheathing of the frame with metal profile

It should be noted that most of the profiled sheets have a width of 1-1.2 m. Namely, starting from these parameters, the frame of the garage was assembled. Or rather, intermediate elements were installed. It is important to assemble the casing so that the two profiled sheets are stacked on top of each other with overlap in one wave. As is usually done when covering roofs. It turns out one hundred percent hermetic construction that does not allow atmospheric precipitation and wind.

It is important, given the size of the garage structure, to precisely trim the profiled sheets in length. Therefore, in the workshop it is better to take a drawing of the building with the specified dimensions. The foremen themselves will determine the length of the metal sheets.

With regard to installation, there is no problem. Corrugated trimmed exactly to the size. It remains only not to confuse where to install a sheet. And one more thing - the elements of the skin are set vertically. Fastening cladding is carried out using metal screws. They have a drill at the end, with the help of which profiled sheeting is drilled without first drilling holes. The screwing step of the screws is 30 cm.

The video shows how to install profiled sheeting to the metal frame of a garage building:

Installation of gates

The front wall, where it is planned to install the gate, does not close with a professional flooring. The gates themselves are made of the same material as the building framework. The main task of the work producer is to make the production precisely so that the door leaves close tightly and open freely.

Each hinge will require two loops. The most difficult task is to precisely set the doors in height, and that the loops, or rather, their two parts coincide with each other. Therefore, the frame is first made garage doors. In fact, these are two rectangles, inside which additional elements are installed that give structures rigidity. These can be sections of profiles, installed vertically or horizontally, or diagonally. In some cases, use a combined installation. The photo below shows a sketch of the combined frame of a garage door.

How to install the doors correctly:

-

To them weld a part of the loops with a spike.

-

Folds raise and place each at the required place, substituting, for example, bricks.

-

Align the with the building level, leaving a small gap between the leaves.

-

The second parts of the loops are applied so that the spike of the upper part fits into the groove of the lower part. They are immediately welded to the corner box frame element.

-

So do with each element . Then remove the bricks and check how the gate closes.

Then the ears for the padlock, the handle, the loops for the bolt are welded to them. And in the end sheathe profiled. In fact, you should have something like this, as in the photo below.

It can be interesting! In the article on the following link read about 151> technologies and materials for finishing the ceiling in the garage .

Thermal insulation of the garage

It should be noted that such a garage, covered with a metal profile, is a cold structure. It will protect the car from atmospheric precipitation, and it has a good crack resistance. But the temperature outside and inside the garage will be the same. And in winter it is not always good. Therefore, it is recommended to warm this garage.

Mineral wool boards or foam polystyrene plates can be used for this. As for the first insulation, it is necessary to choose a moisture resistant option. The thickness of the heat-insulating layer should not be less than the thickness of the metal profiles used in the assembly of the frame.

Heater is simply placed between the posts of the frame structure. It is important to cut the insulation material so that it fits tightly between the elements of the frame structure. From above it is recommended to close all the surfaces of the waterproofing membrane. It will protect the heat insulator layer from wet vapor on its surface, which immediately on it will turn into condensate droplets. And moisture reduces the life of insulation.

From inside the garage can be sheathed with different materials: plywood, OSB, chipboard, MDF, the same decking and other.

The video shows how to insulate a metal garage with polystyrene foam plates:

How much does it cost to order the construction of a garage from a metal profile

Today, the market offers a fairly large number of proposals from companies offering to assemble a metal profile garage (the cost varies for different reasons). Of course, the main reason is the size of the structure. The more, the more material goes, hence the high price. We will show the averaged values in the country:

-

a garage with dimensions of 3x6x2.3 m costs 75000-80000 rubles without facing with a metal profile. with plating - up to 126,000 rubles. ;

-

4x6x2.1 m - 100,000 and 140,000 rubles, respectively. ;

-

6x6x2.1 m - 125000 and 210000 rubles respectively.

The video says that the production of garages from corrugated flooring is a great opportunity to start a business:

This could be interesting! In the article on the following link read about a country house with a porch .

Conclusion on the topic

The frame garages, sheathed with metal profiles, are again popular and in demand today. And in terms of lining profiled - the perfect solution. Ready designs are offered two executions - folding and not folding. In the first case, the fastening of the garage construction units is carried out on bolts or self-tapping screws. A convenient option in the sense that the building can always be quickly disassembled, transferred to another place where it is re-assembled.