The development of building technologies leads to an improvement in the quality of construction. The materials checked by time are combined in a new way, giving rise to unexpected combinations with impressive properties. So it was with concrete. The material, widely used by the builders of ancient Rome, after a series of experiments became the ancestor of lightweight concrete.

Foam concrete can be considered one of the most successful and common varieties of this group. The maximum use of the best material properties allows foamed concrete blocks, whose characteristics best meet the requirements of building codes.

What is foam concrete - all you wanted to know

Foam concrete refers to a group of cellular concrete. It is often confused with aerated concrete, which differs in composition and in final processing technology (it can be autoclave or non-autoclave).

The foundation of foam concrete is sand, water, and cement. The production technology has practically not changed since the 30s of the last century. Foam-based additives, organic or synthetic, are fed into the cement mortar. Additives churn the mass of the solution, saturating it with air bubbles and increasing the volume. The bubbles are distributed in the mixture, and during solidification they leave closed cavities (cells). Such pores reduce the density of the material; besides lightness, concrete acquires other properties useful for construction.

Since a cement binder is used for the production of cellular concrete, its strength continues to increase over a long time after production (checks showed that the strength increases 3-4 times after 30-40 years of operation).

Production technology of foam concrete blocks

Foam concrete production does not need to build a complex technological chain . Cement-sand mixture is placed in a tank-mixer, where additives are fed from the foam generator in the form of foam in an aqueous solution. The blowing agent complex increases the strength and frost resistance of the material, reduces thermal conductivity and shrinkage during drying. Foaming agents of two types are common:

-

Organic (protein origin). The product is environmentally friendly and more durable (the walls of the cells are thicker).

-

Synthetic. The material has a hazard class 4 (can release toxic substances) and is less durable; not recommended for residential construction.

Sometimes, VSM fiberglass (building fiber, microreinforcing fiber) is used as an additive to increase the strength of the material or dry ash (fly ash), which allows to save cement.

The mixing of the initial components takes place under pressure. Then the mixture is cast in special forms (cassettes) or in monolith. In the second case, after drying, the mass is cut according to specified dimensions.

Excess water evaporates during drying. Hardening occurs in a natural way, which reduces the homogeneity of the fine-mesh structure (compared to aerated concrete). The simplicity of the process allows you to prepare foam directly on the construction site. The material turns out to be cheap, since its production takes 2-4 times less cement.

Technical characteristics of foam concrete

With the growth of low-rise construction volumes, the popularity of foam concrete products is increasing. Foam blocks, the sizes and prices of which are very variable, also attract with their set of technical and operational properties.

Advantages and disadvantages of the foam block

-

Low density. Constructions of lightweight material exert the minimum possible pressure on the foundation (the density is 4 times less than that of claydite-concrete).

-

Strength. Allows you to build bearing walls (in buildings up to 3 floors of brands from D900 and above).

-

Thermal Conductivity. Lower than ordinary brick 3-4 times. Low thermal conductivity provides comfortable living conditions in any climate, keeping the room cool in summer and warm in winter. The consequence is energy saving.

-

Sound insulation. An important factor in urban settings.

-

Fire hazard. Foam concrete refers to non-combustible materials.

-

Moisture resistance. The blocks, made according to GOST, have almost no open pores and are able to stay on the surface of the water for days without absorbing it.

-

Sustainability. Foam block with organic blowing agents does not emit toxic substances.

The disadvantages include the low-aesthetic appearance of the building, which requires finishing. It is also necessary to monitor the geometry of products. Due to the uneven surface, the width of the mortar joints increases.In order that the thermal conductivity does not deteriorate, the parameter must not exceed 2 mm; for which it is more convenient to use glue.

On our website you can familiarize yourself with the most popular projects of foam concrete blocks from construction companies represented at the exhibition “Low-Rise Country”.

Unique advantages enjoyed by the

-

foam block Saving money. The material itself is cheap, which allows you to save on the purchase. Plus, thanks to the ease of foam blocks, the foundation for the house can be made less powerful, which also reduces the budget. Reduced costs for transportation, storage and masonry walls.

-

Save time and effort. Foam block, the size of which is much larger, and weight less than that of a brick, allows you to simplify and speed up the construction process.

-

Ease of processing. Foam blocks are easy to cut, drill and shtrobit with a standard tool, a grinder or a manual hacksaw. This simplifies all types of work - finishing, plumbing and electrical wiring.

Disadvantages of foam concrete blocks, which sellers are silent about

Foam concrete blocks are a proven raw material for private construction and wall insulation of finished buildings. Like any material, foam concrete has a number of features, ignorance of which leads to misuse and frustration.

Low compressive strength

In an effort to reduce production costs, the manufacturer can use low-grade raw materials (cement). When purchasing a batch of blocks worth checking certificate. You can check the brand strength by hammering a 10 cm long nail into the foam block. The strength is normal if it cannot be removed with your bare hands.

The manufacturer seeks to avoid additional storage costs for finished products. Brand strength of foam concrete (100%) is achieved only on the 28th day after production and further increases over the course of decades. The use of blocks before the expiration of this period (1 month) may lead to shrinkage and the occurrence of cracks in the finished structures.

It might be interesting! In the article on the following link read about two-story projects houses.

Construction features

-

Foam concrete structures need reinforcement, which is carried out on every 4-5 row of blocks and next to the openings, even for single-story buildings. It will allow to carry out reliable installation of overlappings and rafter system.

-

Blocks for facade finishing must have a frost resistance coefficient of 50 (the ratio of the traveling blocks D500 varies between 25-35), otherwise deformations are inevitable.

-

For finishing walls use special plasters and paints; The usual finish is deformed and guaranteed to be covered with cracks. The design during the work should be protected from waterlogging.

-

Under the conditions of the middle band, the minimum thickness of the masonry should be 640 mm (the standard block has a thickness of 500 mm), the foundation is preferably monolithic tape.

Features of fasteners.

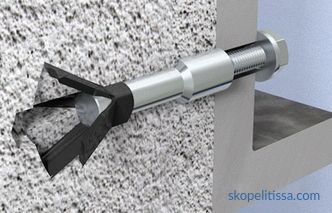

Although self-tapping screws and nails are screwed into aerated concrete like a tree, they hold it badly; Due to the low mechanical strength, the porous material crumbles easily. If you need to hang something heavier than the picture, standard dowels or anchors are not suitable. When installing furniture, electrical equipment or plumbing fixtures, they are specially designed for porous walls. It is made of metal, plastic or nylon; There are chemical anchors with fixation on the glue base.

Main applications of foam blocks

Foam blocks are widely used for the construction of residential and industrial buildings. They are used in:

-

Construction of load-bearing walls. Fit blocks of durable varieties.

-

Construction of interior walls.

-

Thermal Insulations. Foam blocks of minimal density are used, since their heat-insulating (as well as sound-proof) properties are maximum.

You can see the video about foam concrete and its features:

Types and characteristics of foam blocks (standard sizes and weight)

Foam concrete blocks, the sizes and prices of which fit into several classes, are divided according to their density (number of air cavities per unit volume) and destination. The smaller the pores, the higher the density, thermal conductivity, strength and dimension of the brand.

-

Construction blocks. Brands D1000-D1200 are used for load-bearing structures. Such blocks assume the weight of the floor, the next floor and the roof. They have maximum strength and weight.

-

Combined blocks (structural thermal insulation).D600-D900 grades are suitable for load-bearing structures and effective thermal insulation in private construction.

It might be interesting! In the article on the following link read about the projects of houses 8 to 8.

-

Thermal insulation. Lightweight units with maximum thermal insulation, suitable for internal partitions. Used brand D100-D500.

The standard size of a foam block for building a house has several options. A standard wall block with a size of 600x300x200 or 600x400x200 mm is most often used for external load-bearing walls, for internal load-bearing walls - 300x200x600 mm, partitions are laid using blocks of 100x300x600 mm. The scatter is associated with the peculiarities of the formation of different types of clutch.

The weight of the blocks depends on the brand (it is different for blocks of the same size, but different brands).

It is important to understand that over time, under the influence of weather conditions, the weight of foam blocks will inevitably grow. This is taken into account when designing the foundation.

There are tables in which you can trace the change in weight depending on humidity. The weight of the wall block (with an initial weight from 10.8 to 43.2 kg) can vary from 11.7 to 47.5 kg (with a relative humidity of 75%).

Prices for foam blocks

The price of a foam block depends on the manufacturer and brand. Average prices:

-

A building block of standard size 600x300x200 will cost 3200-4500 rubles. / 1 m³.

-

The construction and heat insulation block (wall) - 120-140 rubles. /PC. ; half block - 60-75 rubles. /PC. ; The average price of 1 m³ varies between 3200-3800 rubles.

-

The heat-insulating block of the brands D100-D500 and 400x200x600 mm in size will cost 2700-3000 rubles. / 1 m³, 1 unit costs 117-120 rubles.

The dimensions of foam concrete blocks may vary from different manufacturers. When buying, you should pay attention to the color and quality of the surface of the material. High-quality foam concrete should have a uniform grayish color. By technology, blocks cannot turn bright white; violation of the process leads to fragility. On a smooth surface should not be chipped and cracked, the cells are not connected to each other.

What is more advantageous to use in the construction of objects: aerated concrete block or foam block

-

Isolated air pores in foam blocks prevent the wall from breathing and poorly transmitting heat. Therefore, for additional insulation of foam concrete structures, you can use foam. Aerated concrete with breathable structure, it is recommended to warm the mineral wool, breathable.

A clear comparison of foam blocks and gas blocks in the video:

-

The gas block exceeds the foam block in strength 3-4 times (if we compare brands with equal density); plaster on it lies smoother. At the same time, aerated concrete easily absorbs and gives up moisture. At the same density, the foam block floats on the surface of the water, and the aerated concrete partly submerges in water.

-

The porosity of aerated concrete is more homogeneous than that of foam concrete; this is due to the peculiarities of production. Due to the pores of different sizes, the thermal conductivity of different foam concrete blocks may differ.

-

The wall of foam blocks absorbs moisture more slowly than it does from gas blocks. But both facades need protection from direct contact with water.

-

Aerated concrete is produced from natural ingredients. In the production of foam blocks used foaming agents of synthetic origin, which can harm human health.

-

Foam concrete blocks are more profitable (cheaper) than aerated concrete. But the cement mortar for the masonry will spend more money than glue.

It can be interesting! In the article on the following link read about projects of houses up to 150 m.

Conclusion

And gas and foam concrete blocks serve as a versatile material that has found wide application in private construction. They are used for laying of bearing walls and partitions, interfloor ceilings. With their help, they warm the external walls and basements. They are successfully used for the construction of garages and buildings for household purposes. In any case, in order for the building to be strong and durable, the material should be purchased from a trusted manufacturer with good recommendations. It is also important to consider the features of the material.