The article provides information on how a collapsible brazier is made. What are its dimensions, what materials are used for this. Whether it is required for the manufacture of a drawing. If "yes", then what is necessary to pay attention to, which parameters are important given the ease of use of the roaster under the kebab. Considered the production of mangal step by step.

Brazier dimensions

Understanding the brazier sizes for iron skewers according to the drawings, presented on the Internet, one can only say that among them there is only one standard parameter - the height of the sides. It varies in the range of 13-15 cm. You shouldn’t do less - the kebabs will burn, high altitude - you will have to prepare more coals, and these are expenses and time.

All other sizes are at the discretion of the customer:

-

width is selected depending on the length of the skewers used;

-

length depends on the number required shish kebab in terms of simultaneous frying, for example, if a gap of 5 cm is left between the skewers, plus the width of the meat itself, you will get within 8-10 cm, if you need to fry 10 sticks, the length will be within 1 m;

-

height depends on how to cook on the grill: standing or squatting, in the first case it is 70-80 cm, in the second 20-30 cm;

-

as regards sheet thickness Eza, then for a folding design the size in 2 mm will be suitable, but for a bottom it is better to use three-millimeter metal.

Manufacturing technology of folding brazier

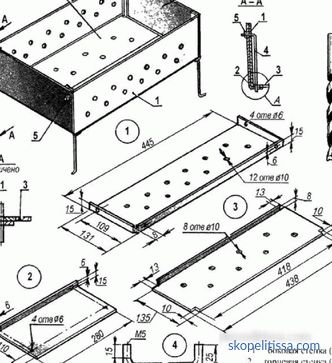

First the queue is set on paper by a drawing of a mangal with the designation of dimensions on it. In purely constructive terms, this device is a parallelepiped. That is, he has all the opposite pair walls are equal to each other. The only plane that is present in a single-hearth pan is the bottom.

It is necessary to approach development of drawings of braziers thoroughly. Because it is the basis of future design. It displays the proportions of the roaster. And although this is of minor importance for the portable collapsible version, a certain aesthetic side should be present in the design.

In the drawing below, which shows the complete detailing of the structure. That is how the masters throw it on paper. The main task is to show the dimensions of each part, because they are made each separately. And the exact dimensions will help to combine the parts into a single unit without fittings.

If the drawing of the barbecue from metal with dimensions is ready, the master proceeds directly to making the brazier.

It can be interesting! In the article on the following link read about barbecues with a roof.

Materials

As mentioned above, a steel sheet with a thickness of 2 and 3 mm is required as a material. As legs you can use reinforcement with a diameter of 10 mm. To connect the parts of the roaster it will take eight bolts M6 or 8.

Marking

According to the drawing, all the dimensions of the barbecue parts are transferred to the iron sheet. As already mentioned, the side walls will be two, the end, too, the bottom one part. Paired walls are the same.

It is impossible to scatter markup on the whole sheet. Many of the dimensions of the parts are the same, so that the edges of the two parts will be denoted by a single line. So you can save money by reducing waste.

Cut metal sheets can be found on the market. If it is correct to put together (make correctly the layout of the parts) markup, then you can buy not a whole sheet, but a trimmed one. It costs several times cheaper.

Now the important point. The connection of the parts of the brazier is made on the bolts (as one of the options), therefore, under the joints, the sides are made, which are bent inward from the main plane of the walls by 90 °. In this case, on the side walls, the limb is made on three ends with fastening to the end walls and the bottom, on the end walls only from this side - to the bottom. The width of the limb:

-

if the M6 bolt is used for the connection - 10 mm;

-

if the M8 bolt is 12 mm.

This parameter is necessarily added to the dimensions of the parts. For example, if the length of the brazier is 50 cm, then the length of the side walls is 52 cm, because the limb is added to it from both sides by 1 cm.

Cutting, bending, drilling

Next stage - cutting all parts of the barbecue exactly along the marking lines. Usually this is done by a grinder with a detachable diamond disc. You can use other tools: plazmorez, jigsaw with a blade for metal. Cutting should be carried out exactly on the applied markup. Everything must be done carefully.

In the end, you should have five parts: side panels - 2 pcs. , end - 2, bottom one.

The next operation is the bending of the joints of the parts of the barbecue.On the cut details of the brazier, indents for bends are applied. Again the ruler and marker are used. On the side walls there will be three lines: two parallel (for connection with end walls), one perpendicular to them (for connection with the bottom). On the end walls of one line. It should coincide in location with the line for the bottom.

A shallow cut is made on the applied lines; it is not continuous, but with a small recess to 0.5 mm. This is done in order to bend and flex more easily. Pay attention to the side walls, where the cuts of the perpendicular lines will create squares in the two corners. They are cut off completely.

Now bends are made with a hammer. The workpiece is placed on the edge of the table, it is better if it is trimmed with a steel corner, and with light strokes bend the edge of the limb along the undercut. Bending angle - 90 °.

It might be interesting! In the article the following link read about the brick grill for home and garden.

The next stage is the formation of junctions. To do this, in the bends of the side walls with an indent from the top and bottom edges inward of 3 cm, a mark is made a marker. Through holes are drilled through them.

Next, one end wall is applied to the side as they should be assembled. Through the holes made on the plane of the end wall marks are made, which are also drilled.

Immediately it is necessary to designate that the bottom of the brazier is not fixed to the walls. It simply lies loosely inside the box of side and end parts, resting on bends on four sides.

It remains only to drill holes in all parts of the brazier. They intend that the fresh air saturated with oxygen, got into a zone of burning of coals. Without air, the embers will not be able to give the maximum amount of heat, from this frying kebab until readiness is delayed.

In principle, a homemade barbecue is ready. It remains to assemble and bolt.

Making legs

There are a lot of options here. Often they are made of sheet iron with a thickness of 3 mm, bending the letter "Z". For this, it is only necessary to make holes for bolts in the bottom of the brazier and in each leg.

More reinforced design - from reinforcement or pipes of small diameter. The main thing - to choose a way to connect the legs with a barbecue (collapsible). The easiest is to weld a bolt to the leg, make a hole in it in the bottom. Bottom leg bolt inserted into the grill and tightened the top nut.

There is another option - it is welded to the lower edges of the end or side walls of the brazier in places where the legs of the tube are installed with a diameter slightly larger than the diameter of the reinforcement. The length of the tubes is 3-4 cm. That is, the legs when assembling the brazier will simply be inserted into the tubes. It is impossible to weld to the bottom, because this element is not fixed to the construction of the brazier. There is one moment in this variant - limiters are welded to the legs in the form of washers or perpendicular transverse rods made, for example, from a rod 6 mm in diameter. Although there are many options.

You can add a folding device for frying kebabs with various convenient devices. For example, handles for raising the whole structure in the form of rings welded by electric welding or bolted to the end walls. You can do without pens, making slots for fingers. Today, barbeque grills are popular, that is, provided with a lid and a net on which meat, poultry or fish are placed.

The video features a folding grill-book:

On our website you can find contacts of construction companies that offer installation services for stoves and fireplaces, and also various turnkey metalwork. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Conclusion

As an example, one type of collapsible barbecue was considered: its dimensional drawings, manufacturing technology and assembly. The main task of the manufacturer is to choose the correct dimensions of the structure and coordinate them with the customer. If you have any specific requirements, it is advisable to discuss them with the master - the convenience of further use of the barbecue and the quality of cooking depends on it.