The article contains information about roofing for roofs of private houses - "Ondulin". On its technical characteristics, installation technology, characteristics. You will learn what positive and negative sides the ondulin roof possesses and get information about the basics of calculating the material for arranging the roof.

A bit of history

Ondulin, who is also a euroslate, got its name from the name of the company which began to produce it. This happened in 1944 in France, when after the war there was a shortage of building materials. The demand for them was high, but the products were not expensive. Therefore, the company "Onduline" began to produce slate, which instead of asbestos made cellulose. A binder was a binding component.

The roofing material was therefore environmentally friendly, and its cost was low. The French company besides ondulin released its subtype under the name "ondur". In principle, this is all the same roofing wavy material, only its size is larger than ondulin. Therefore, its main use on roofs with large areas of slopes.

It should be noted that one of the American companies also produced pulp bitumen sheets with undulating molding. They called their products "Nulin". Since the company "Onduline" tried to keep the global market for ondulin consumption in its hands, in 2010 it simply bought an American company.

We add that the French did not carry products across all countries. They preferred to take root in them, organizing production. So in 1994 a plant was built in Nizhny Novgorod. Therefore, ondulin on the Russian market is represented by products of this plant. Although it should be noted that small productions are also present. But the quality of their material leaves much to be desired.

Singleline production technology

As mentioned above, ondulin for the roof is made on the basis of cellulose fibers and purified bitumen. Fortunately, all this in Russia is in unlimited quantities. For example, cellulose is made from waste from the woodworking industry, the production of cardboard and paper, wooden building materials, and the collection of waste paper.

The very process of producing ondulin is simple:

-

The pure pulp is mixed with special additives that increase the plasticity of the resulting mixture and the strength of the final product. At this stage, pigments are added that dye ondulin in the whole body.

-

The resulting mixture is rolled into a strip of a certain thickness and width.

-

Slate is molded by pressing. The process occurs at a certain temperature and pressure. It is in this area that the pulp is impregnated with bitumen.

-

Coloring on two or one sides.

-

Drying.

-

Cutting into sheets to the required dimensions.

-

Packaging and warehousing.

On our site you can find contacts of construction companies that offer roofing services of any complexity. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

Characteristics of ondulin

Let us immediately designate that under the brand "ondulin" two models are produced: DIY and SMART. They differ in the width, which is respectively equal to 760 and 950 mm. Of course, the number of waves they will also be different: 8 and 10. Otherwise, they have no differences. Here are other dimensions:

-

length - 1950 mm;

-

thickness is 3 mm;

-

the height of the ridge is 38;

-

the wave step is 95;

-

the specific weight of the sheet is 3.4 kg / m².

And ondulin's technical characteristics:

-

density - 0.87-1.15 g / cm³;

-

strength - 6.5 MPa;

-

bending strength: at -40 ° C - 23 MPa, at + 20 ° C - 7 MPa;

-

maximum operating temperature: + 110С;

-

frost resistance - 25 cycles;

-

water absorption - 1.5%.

Calculation of the ondulin number

Note that this roofing material is the total area of the sheet and useful. The basis of the calculation is to take the second indicator. The fact is that ondulin fits overlapped between adjacent sheets along the eaves and with a slight displacement along the slope. This reduces its total area. In addition, the slope of the roof slope must be taken into account in the calculation. Here is the dependence of the usable area on the slope of the roof (by model).

| Roof steepness | Useful area of ondulin, m² | |

| DIY | SMART | |

| 10 ° | 0.94 | 1.25 |

| 11-15 | 1.16 | 1.5 |

| greater than 15 | 1.22 | 1.56 |

On our site you can find contacts of construction companies that offer a range of construction services without making a prepayment. Directly to communicate with representatives, you can visit the exhibition of houses "Low-rise Country".

The calculation of the amount is simple. It is necessary to determine the area of the roof slope. Then determine the angle of inclination. And, by selecting the parameter according to the table, divide the roof area by the ondulin area. The resulting figure increase in a big way.

Ondulin is more often used in the construction of single or gable roofs. If the roof has a complex structure, then there will be a lot of waste material. Therefore, the company "Onduline" today offers a unique material called "Onduvilla". It is a bit like a metal tile. When used on complex roofs, there is not much waste.

Ondulin Mounting Technology

Onduline Roofing is first of all choosing the right type battens: discharged or solid. If the roof slope is in the range of 5-10 °, then a continuous sheathing is mounted, more than 10 ° - discharged.

For a continuous batten, you can use boards with a thickness of 20-25 mm and a width of 100-150 mm. As well as sheet or slab materials: moisture-resistant plywood, OSB, chipboard and so on. An important point - docking elements of crates produced on rafters. Plates and sheets must be laid out in a run, optimally in half a sheet. And between them a compensation gap of 1-2 mm is always left. This is in case of thermal expansion of lumber.

As for the discharged lathing, if the angle of the roof slope is within 11-15 °, then boards with the above parameters are used. In this case, the mounting pitch is 45 cm. If the angle of inclination exceeds 15 °, then wooden slats with a section of 50x50 mm are used. Their installation step is 61 cm. Note that the pitch is the distance between the middle of the boards or the laths .

It might be interesting! In the article on the following link read about painting the roofs of a private house.

Installation of an ondulin

Proper installation of an ondulin on the roof is determined by certain conditions:

-

installation is best done on the leeward side if the house is being built on a site prevailing winds acting in one direction;

-

at outdoor temperatures below + 5C it is better not to cover the roof with ondulin;

-

at temperatures above + 30C, the material becomes excessively ductile; therefore, it is recommended not to perform installation in this heat.

Now, as for the overlap of adjacent sheets. Everything here also depends on the angle of the roof. Laying with an overlap is made in the transverse direction, here the number of waves is taken into account, and in the longitudinal.

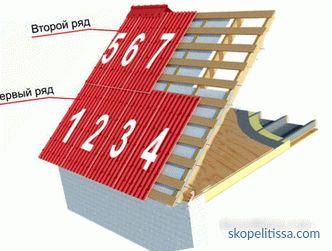

If the angle of inclination varies from 5 to 10 °, then in the transverse direction the sheets overlap in two waves. In the longitudinal within 30 cm. When the roof is tilted within 11-15 °, laying is carried out transversely in one wave, longitudinally - 20 cm. At an angle above 15 °: transversely - 1 wave, longitudinally - 12 cm. Laying scheme

There are two options: linear and ladder. The first is when the sheets are stacked one on another in the longitudinal direction from the eaves to the ridge. The second is when the elements of the roofing material are stacked with an offset of half a sheet. That is, the first row begins with a solid panel, the second (upper) half of the sheet. It turns out that the joints between the sheets in the same row fall in the middle of the sheets of the next row.

Attaching sheets

Attach the ondulin to the crate with special nails. They have a wide cap and a rubber (neoprene) gasket. The latter under the negative effect of natural loads does not change its characteristics, size and shape. Nails are driven into the upper wave. The manufacturer has recommendations regarding the number of nails per unit of roofing material. So the DIY model requires 15 nails per panel, for SMART - 20.

This can be interesting! In the article on the following link read about attic insulation from the inside if the roof is already covered.

Please note that fastener caps are painted in different colors. This makes it possible to choose the color of the color to match the painted surface of the roofing material.

Now about the order of nailing. First of all, you need the first sheet, which is located in the lower corner of the ramp, exactly set in the plane.The easiest option - between the extreme rafter legs at their lower ends to tighten the thread, which is attached to the screwed screws. That is, the thread determines the evenness of the eaves. She is put in a horizontal plane, and on her put sheets of ondulin first row.

At first the sheet is hammered with four nails at the corners of the panel. At the same time, it is not fully clogged so that it remains possible to once again check whether the roofing panel is installed correctly. Then slaughtered until it stops.

Material is fastened along the first row of the sheathing into each wave. The remaining rows through the wave, but in a staggered manner with respect to the rows.

When building a roof made of ondulin, some points should be taken into account:

-

nails do not curl into a wave that overlaps a joint;

-

fasteners must be hammered into a wave adjacent to an overlap;

-

along the top edge also, sheets are not fastened.

This is how the roof of ondulin is assembled in rows. Although there are other schemes, for example, 3-4 sheets fit in the first row, then a second row of 2-4 panels is assembled, and so on along the rows to the ridge.

We add that Onduline offers all the elements of the roof. This is a ridge element, gable, for the valleys, as well as curtain strips. They are attached to the roof in the same way as in the case of corrugated or metal roofing.

Video, how to install the ondulin on the roof correctly:

It can be interesting! In the article follow the link read about the restoration of the family house.

Conclusion on the topic

It is necessary to indicate that the company "Onduline" produces Ondulin only by itself. She does not give anyone any rights. All plants operate according to a single standard and technology. The company sells roofing material only through distributors with whom it contracts. Therefore, not all hardware stores is exactly the product from "Onduline". Require a quality certificate from vendors that confirms the manufacturer.